When it comes to industrial machinery, journal bearings play a pivotal role in ensuring the smooth operation of various components. However, the failure of these bearings can lead to catastrophic consequences. At Fusion Babbitting, a leading company in bearing journal repair, we understand the significance of early detection to prevent breakdowns and costly repairs. One of the most overlooked warning signs of journal bearing failure is often missed, yet recognizing it can save both time and money.

Understanding Journal Bearings and Their Importance

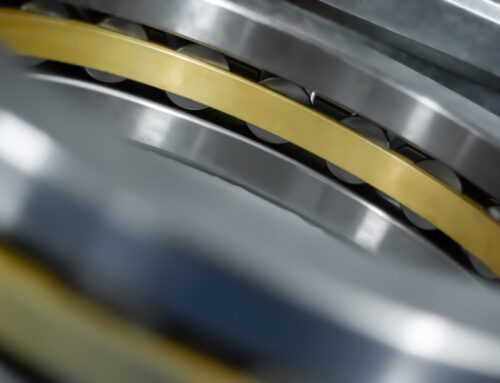

Journal bearings are critical components found in a wide range of machinery. They support rotating shafts and help reduce friction during operations. These bearings are essential in sectors like aluminum mills, cement and chemical plants, hydro/pump storage, and even shipyards. Ensuring their optimal function is, therefore, crucial to maintaining the efficacy and longevity of industrial equipment.

Fusion Babbitting Co., Inc., based in Milwaukee, WI, has specialized in the repair, rebabbitting, and rebuilding of journal bearings since 1988. With over four decades of combined experience, Fusion Babbitting is committed to delivering high-quality bearing repair solutions that meet or exceed OEM specifications.

The Most Overlooked Warning Sign: Vibration

Why Vibration Matters

Vibration in machinery is a common occurrence, but excessive vibration is a telltale sign of potential journal bearing failure. While many operators interpret vibration as a normal aspect of machinery operation, failing to address abnormal vibrations can lead to severe damage. At Fusion Babbitting, we emphasize understanding these subtle signals as a preventive measure against bearing failure.

How to Recognize Problematic Vibrations

Excessive vibration can be recognized by an increase in noise levels, unusual rattling sounds, and even perceivable shaking of the machinery. If any of these symptoms are noticed, it is crucial to contact experts like Fusion Babbitting for a thorough evaluation and professional bearing journal repair to prevent further damage.

Fusion Babbitting: Your Trusted Partner in Bearing Journal Repair

Fusion Babbitting offers a comprehensive suite of services, designed to cater to the diverse needs of industries such as fossil and nuclear plants, motor repair shops, mines and steel mills, and paper mills. Our experts are equipped with advanced equipment and the latest techniques to restore your machinery components to their original specifications.

Our Specialized Services

– Repair, Rebabbitting, and Rebuilding: We ensure each repair meets or exceeds OEM standards, providing durability and reliability.

– Centrifugal Casting: This technique uses certified Babbitt materials to guarantee strong bond strength and bearing integrity.

– Arc Flame Spray Application: Designed to restore worn components to their original specifications, enhancing the lifespan of your machinery.

– Reverse Engineering: Our experts can create exact replicas of obsolete bearings, ensuring your equipment remains operational.

– General Fabrication and Machining: Capable of handling components up to 120 inches in diameter and length.

– New Manufacturing: Custom, high-precision bearing products tailored for OEMs.

The Importance of Timely Intervention

Timely intervention can make all the difference when dealing with potential bearing failures. At Fusion Babbitting, our 24-hour emergency services highlight our commitment to ensuring your machinery functions seamlessly at all times. Waiting too long before addressing the signs of journal bearing failure can increase repair costs, downtime, and even lead to further machinery damage.

Additional Warning Signs of Journal Bearing Failure

In addition to vibration, operators should look out for other warning signs that may signal bearing failure. These include:

– Unusual temperature increases: Bearings that are overheating can indicate poor lubrication or excess friction.

– Oil discoloration: A change in the color of bearing lubricants can suggest contamination or wear.

– Audible sounds: Grinding or whining noises may point to deteriorating bearings.

Recognizing these signs early allows for timely repairs and can extend the life of your machinery.

Protecting Your Investment

Industrial equipment is a significant investment, and ensuring its longevity is essential for preserving operational efficiency and reducing overhead costs. By partnering with Fusion Babbitting, companies can take proactive steps to safeguard their machinery. Regular maintenance and early intervention through expert services help prevent potential disruptions and keep your operations running smoothly.

Contact Fusion Babbitting Today

Bearing failures are avoidable when recognizing the early warning signs and taking action swiftly. Fusion Babbitting offers unparalleled expertise and reliable services, making us the go-to solution for bearing journal repair needs. Our team is ready to assist with any inquiries or service requests you may have.

For more information or to schedule a service, reach out to Fusion Babbitting at our Milwaukee office:

Address: 4540 W. Burnham St., Milwaukee, WI 53219

Phone: 414.645.5800 | Toll-Free: 800.613.5118

Email: sales@fusionbabbitting.com

By choosing Fusion Babbitting, you’re opting for a partner committed to the uptime and reliability of your industrial operations. Don’t overlook the subtle signs of journal bearing failure; let us help you maintain peak performance today!