Quality Control

Fusion Babbitting Co., Inc. is dedicated to all our customers by striving to continuously improve the performance, quality, and value of our products and services. Our quality assurance system focuses on the following principles:

-

-

- Quality is the responsibility of every employee

- Ethical workmanship and customer satisfaction are vital

- On time delivery at the agreed upon price

- ISO 9001: 2015 Certified Click here to view our certificate

- 10CFR50 Appendix B, Quality Assurance Criteria for Nuclear Power Plants and Fuel Reprocessing Plants.

-

We use only virgin grade Babbitt, all Babbitt is certified by an independent laboratory to ensure the highest quality:

| BABBITT SPEC. NO. | TIN % | COPPER % | ANTIMONY % | LEAD % | ARSENIC % |

|---|---|---|---|---|---|

| ASTM B23 – 49 GR.1 | 90 – 92 | 4 – 5 | 4 – 5 | .35 max | .10 max |

| ASTM B23 – 49 GR.2 | 88 – 90 | 3 – 4 | 7 – 8 | .35 max | .10 max |

| ASTM B23 – 49 GR.3 | 83 – 85 | 7.5 – 8.5 | 7.5 – 8.5 | .35 max | .10 max |

| SAE 11 | 86 – 88 | 5 – 6 | 6 – 7 | .35 max | .10 max |

| SAE 12 | 88 – 90 | 3 – 4 | 7.25 – 7.50 | .35 max | .10 max |

| QQT-390 GR.2 | 88 – 90 | 4 – 5 | 7 – 8 | .35 max | .10 max |

| QQT-390 GR.3 | 83 – 85 | 7.5 – 8.5 | 7.5 – 8.5 | .35 max | .10 max |

| ACM-3021 | 88 – 90 | 3 – 4 | 7 – 8 | .05 max | .01 max |

| ACM-3022 | 82.5 – 84.5 | 5 – 6 | 10 – 12 | .50 max | .10 max |

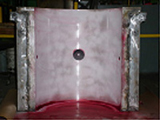

Dye Penetrant Testing

Dye penetrant testing is a quick and cost effective way to determine any weaknesses such as surface cracks, leaks, or porosity issues.

First, we clean the surface of the equipment being tested to ensure all dirt, oil, grease, or paint is removed. This ensures that the test will be able to pinpoint any inconsistencies instead of masking them.

After the initial cleaning, the fluorescent liquid is applied to the surface of the item. It is given time to sit and soak in any impurities.

Once the dye has sat for the necessary time frame (this could be anywhere from 5-30 minutes), the excess penetrant is carefully wiped away. This allows the developer used next to only highlight actual flaws, not just left over penetrant.

Next the developer is applied evenly over the item. The developer reacts with the penetrant and causes what’s known as “bleed out” and shows where the imperfections are on the surface. Then an inspector looks over the item and notes all of the bleed out spots that need to be fixed.

After everything is done, a final cleaning is done to ensure all testing material is off of the equipment and a plan is put into place for a repair.

Bond Quality 99.9% pure tin

Our team takes pride in the quality of our products. We make sure to use high quality materials so that you get long lasting, and reliable products!

MEG Testing

A megohmmeter is used to measure the electrical resistance of insulators on cables in various equipment. Every wire used needs to be tested during production as well as throughout the lifetime of the equipment to ensure everything runs properly and safely.

Level II Ultra Sonic Testing

Ultrasonic testing is a nondestructive test that sends high frequency waves into the material being tested. This type of testing allows inspectors to find flaws deep within a piece of equipment.