Babbitt bearing rebuild stops pump shaft wear at the source. Diagnose root causes, extend equipment life, and avoid downtime. Get a fast expert quote today. If your pump shafts are wearing faster than they should, the problem is rarely the shaft itself. In most cases, shaft wear is a symptom of deeper issues inside the bearing system. A professional babbitt bearing rebuild restores proper geometry, lubrication, and load support so the shaft runs true and your equipment performs like it should. Fusion Babbitting helps plants nationwide turn recurring failures into dependable operation with proven bearing repair and rebuild services.

Why Pump Shaft Wear Points to a Deeper Problem

Visual grooves on a shaft or rapid sleeve wear often lead maintenance teams to replace the shaft and put the pump back in service. The wear returns, sometimes within weeks. That cycle continues until someone addresses the actual cause. In rotating equipment, bearings control alignment, film thickness, and support. If a babbitt bearing loses geometry, has improper clearance, or suffers from poor lubrication, the shaft runs off center or in mixed friction. The result is heat, vibration, and metal transfer that show up as shaft wear.

Common Root Causes of Shaft Wear in Pumps

- Misalignment between driver and pump that forces the rotor to run off center under load

- Incorrect bearing clearances that collapse the oil film and allow contact

- Contaminated lubricant or wrong oil viscosity that reduces film strength

- Out of round housings or soft foot conditions that distort the bearing shell

- Electrical discharge damage from stray currents that pit surfaces

- Unbalanced rotors or hydraulic pulsations that increase dynamic loading

- Improper installation or incorrect fit on the shaft or in the housing

- Cavitation and process upsets that create shock loading

Each of these conditions leaves patterns in the babbitt and on the shaft. Experienced rebuilders read those patterns and correct the causes during the rebuild. This is the difference between replacing parts and restoring the machine to a reliable condition.

What Happens If You Ignore the Signs

- More frequent downtime and higher maintenance costs

- Escalating vibration that spreads damage to seals and couplings

- Energy losses due to friction and misalignment

- Unexpected failures that risk product loss or safety incidents

- Shortened equipment life and higher capital spending

A timely babbitt bearing rebuild stops the wear cycle and returns control of your schedule to your team.

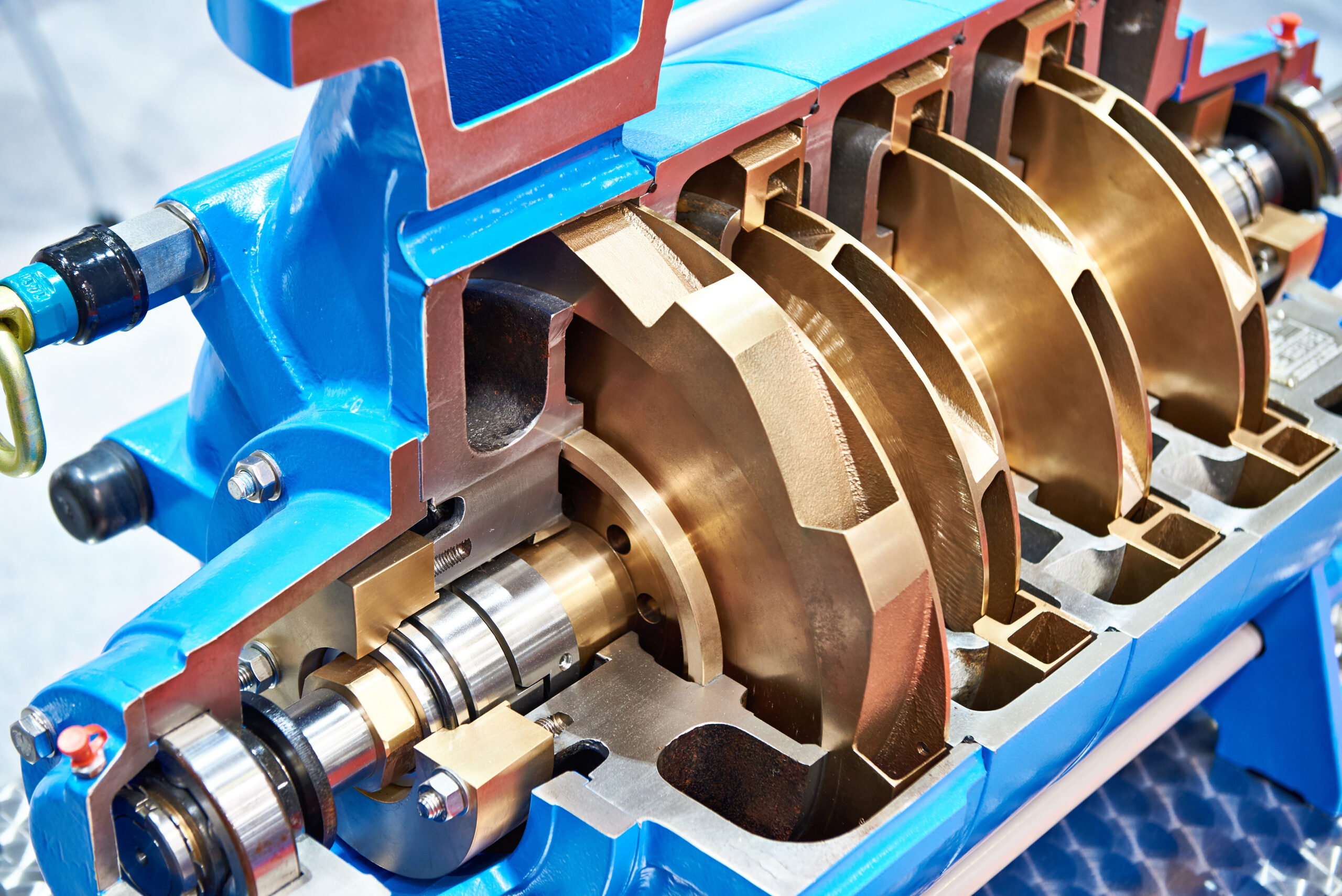

What Is a Babbitt Bearing Rebuild

A babbitt bearing rebuild is a structured repair that restores the bearing to like new condition or better. It is more than pouring new babbitt. A proper rebuild verifies housing roundness, reestablishes centerlines, corrects oil groove geometry, and sets the right clearance for your operating conditions. The process also addresses fits and alignment so the shaft runs centered on a hydrodynamic film.

At Fusion Babbitting, babbitt bearing rebuild includes inspection, rebabbitting, machining, and quality checks that meet or exceed OEM standards. The result is a bearing that controls the rotor position, protects the shaft, and supports high reliability in real world environments.

Rebuild Versus Replace

- Rebuild when the base material and housing are sound, but babbitt is worn or damaged

- Replace when the base is cracked, severely distorted, or outside allowable repair limits

- Rebuild when an obsolete part is no longer available from the OEM and you need a precise fit

- Rebuild when you want to correct OEM weaknesses and apply updated features

Fusion Babbitting can reverse engineer discontinued bearings, create detailed drawings, and manufacture new units when replacement makes more sense than a rebuild.

How Fusion Babbitting Fixes the Cause, Not Just the Symptom

Fusion Babbitting Co., Inc. has provided expert bearing repair and babbitt bearing rebuild services since 1988 from our Milwaukee, Wisconsin facility. Our approach is simple. We diagnose the machine, not only the bearing. Then we rebuild with methods that restore the alignment, bond strength, and oil film conditions that prevent shaft wear.

Our Diagnostic and Root Cause Process

- Gather equipment history and operating data, including vibration, oil analysis, and temperature trends

- Inspect the bearing shell, caps, and housing for roundness, fretting, and witness marks

- Examine the shaft and the worn babbitt to identify load zones and contact patterns

- Measure fits and alignment, then compare to OEM specifications and operating requirements

- Recommend corrective actions, including clearance changes, groove modifications, or fit adjustments

This front-end work ensures your babbitt bearing rebuild addresses the true cause of shaft wear, not only its symptoms.

Our Rebuild Steps

- Disassembly and documentation with photos and measurements of current conditions

- Non-destructive testing of base materials as required to verify repairability

- Machining to prepare surfaces and restore concentricity

- Centrifugal casting of new babbitt using certified alloys for a strong and consistent bond

- Bond testing and inspection to confirm metallurgical integrity

- Finish machining, line boring, and precision scraping to targeted clearances

- Oil groove and dam geometry corrections for stable film formation

- Final assembly, blue checking, and contact verification

- Dimensional reports that meet or exceed OEM requirements

Fusion Babbitting uses centrifugal casting because it produces tight, consistent bonds between the backing and the babbitt layer. This method improves longevity and resistance to load cycling compared to static pours. When housings or journals are worn, our arc flame spray process restores diameters. We spray build up the surface and machine it back to specification so the bearing and the housing fit correctly.

Technologies and Capacity That Support Reliability

- Centrifugal casting with certified Babbitt materials for superior bond strength

- Arc flame spray application to repair worn surfaces and restore fits

- Reverse engineering with detailed drawings for obsolete or one-off parts

- General fabrication and machining capacity for components up to 120 inches in diameter and length

- Custom manufacturing for OEMs and engineered upgrades for field equipment

These capabilities allow Fusion Babbitting to tailor every babbitt bearing rebuild to your exact application and to deliver fast, dependable results.

Benefits of a Professional Babbitt Bearing Rebuild

- Stops pump shaft wear by restoring the hydrodynamic oil film

- Reduces vibration and stabilizes rotor position across load ranges

- Extends bearing and shaft life while lowering total maintenance cost

- Improves energy efficiency through correct alignment and reduced friction

- Shortens downtime with efficient processes and 24-hour emergency service when needed

- Delivers OEM-grade or better quality with full documentation

- Provides a path to replace obsolete bearings through reverse engineering

- Supports reliability programs with measurable, repeatable results

For operators facing repeat failures, a focused babbitt bearing rebuild program often pays back within a single avoided outage.

Industries and Applications Served by Fusion Babbitting

Fusion Babbitting supports clients across heavy industry and power generation with fast, precise bearing services. Our team understands the operating demands of each sector and adapts the rebuild to match real service conditions.

Industries

- Aluminum mills

- Cement and chemical plants

- Fossil and nuclear plants

- Hydro and pump storage facilities

- Marine repair and shipyards

- Mines and steel mills

- Motor repair shops

- Paper mills

- Crushed stone producers

Common Equipment

- Electric motors and generators

- Pumps of all sizes and types

- Turbines and gearboxes

- Hydropower systems and related rotating equipment

Whether you run a river station or a mill finishing line, Fusion Babbitting brings the same engineering focus and attention to detail to every babbitt bearing rebuild.

Early Warning Signs Your Pump Needs a Babbitt Bearing Rebuild

Your team can often spot the need for a rebuild before a failure. Watch for patterns rather than isolated events. The earlier you intervene, the less risk to the shaft and other components.

- Rising vibration in the radial direction or a change in the phase angle

- Oil temperature trending upward under the same load

- Metallic sheen or debris in the oil sample

- Frequent seal failures or coupling wear

- Visible shaft or sleeve wear near the load zone

- Noise during start up or shutdown as the film collapses

If two or more signs appear together, schedule an inspection. Fusion Babbitting can review data, inspect components, and provide a clear plan for a babbitt bearing rebuild that resolves the root cause.

Simple Field Checks Before You Call

These quick checks help you gather information that speeds up troubleshooting and rebuild planning.

- Record vibration at steady state and during coast down to identify mechanical versus hydraulic issues

- Measure housing temperatures near each bearing and compare left to right

- Check alignment between driver and pump at operating temperature if possible

- Verify oil type, viscosity, and contamination levels against OEM recommendations

- Inspect soft foot and baseplate flatness to reduce distortion

- Document clear photos of the shaft wear pattern and bearing load zone for review

Share this data with Fusion Babbitting when requesting a quote. It helps our team tailor the babbitt bearing rebuild to your equipment and duty cycle.

Frequently Asked Questions About Babbitt Bearing Rebuild

How long does a rebuild take

Standard turnaround depends on size and condition. Many pump bearings can be rebuilt within days once materials and approvals are in place. Fusion Babbitting offers 24-hour emergency services for critical outages and can prioritize your job to minimize downtime.

Can you improve on the original OEM design

Yes. Rebuilds are an opportunity to correct clearances, oil groove geometry, or fits to match actual operating conditions. Fusion Babbitting often updates designs to improve film stability, reduce start-stop wear, and enhance lubrication.

What if my bearing is obsolete

Our reverse engineering team can create detailed drawings from your sample, then manufacture a perfect fit replacement. This service is ideal when OEM lead times are long or parts are discontinued.

How do you ensure babbitt bond quality

We use centrifugal casting with certified Babbitt alloys and perform bond testing and inspection. Our process produces a uniform, strong bond that resists fatigue under heavy loads.

Will a rebuild stop shaft wear for good

When the rebuild corrects the root cause and you maintain proper lubrication and alignment, shaft wear drops dramatically. Many clients see extended service intervals and stable vibration for years after a properly executed babbitt bearing rebuild.

Why Choose Fusion Babbitting

Fusion Babbitting Co., Inc. has more than 40 years of combined bearing expertise and has been rebuilding babbitt bearings since 1988. From our facility at 4540 W. Burnham St., Milwaukee, WI, we serve customers nationwide with fast response and dependable results. Our team blends skilled craftsmanship with advanced equipment to deliver precision and repeatability.

- Repair, rebabbitting, and rebuilding that meet or exceed OEM specifications

- Centrifugal casting and strict bond quality control

- Arc flame spray restoration of worn journals and housings

- Reverse engineering and new manufacturing for obsolete parts

- General fabrication and machining up to 120 inches

- Experience across power generation, metals, mining, paper, marine, and more

- 24-hour emergency services to get you back online fast

Every babbitt bearing rebuild we perform is guided by root cause thinking. We do not just pour babbitt. We rebuild the bearing system so your shaft runs on a stable oil film with the right clearances and geometry for the job.

A Practical Example

A process plant reported recurring shaft wear on a critical pump, even after new sleeves were installed. Vibration was moderate but trending up after every outage. During the babbitt bearing rebuild, Fusion Babbitting found out-of-round housing bores and incorrect clearances that collapsed the oil film at operating temperature. We restored the housing fit with arc flame spray and machining, recast the babbitt with centrifugal methods, and reset clearance and oil grooves to match the duty cycle. After the rebuild, shaft wear stopped, vibration stabilized, and the pump ran through the next planned turnaround without issue.

Plan Your Next Babbitt Bearing Rebuild

If shaft wear keeps returning, you need more than a replacement shaft. You need a partner that understands why bearings fail and how to prevent it. Fusion Babbitting brings that focus to every job with clear communication, data-driven recommendations, and reliable scheduling. We stand behind our work and aim to keep your equipment running productively between planned outages.

Contact Fusion Babbitting

Address: 4540 W. Burnham St., Milwaukee, WI 53219

Phone: 414.645.5800 | Toll-Free: 800.613.5118

Email: sales@fusionbabbitting.com

Tell us about your machine, your operating conditions, and your timeline. We will provide a fast, expert quote for a babbitt bearing rebuild that tackles the root cause of shaft wear. Fusion Babbitting is ready to help you restore reliability, reduce downtime, and extend the life of your critical pumps and rotating equipment.

Next Steps

- Collect recent vibration, temperature, and oil analysis data

- Photograph bearings and shafts during your next inspection

- Share OEM drawings if available, or send the bearing for evaluation

- Request a quote from Fusion Babbitting for a tailored babbitt bearing rebuild

- Schedule your rebuild around planned downtime or request emergency service if needed

Babbitt bearing rebuild is the fastest way to end the cycle of pump shaft wear. When the bearing is right, the shaft stays protected. With Fusion Babbitting on your team, you get proven methods, fast turnaround, and a rebuild that fixes causes, not just symptoms. Reach out today and put an end to repeat failures.