Facing a Replacement Bearing Dilemma Without Specifications?

If you’re dealing with machinery downtime caused by a damaged or worn-out bearing, nothing is more frustrating than realizing you don’t have the original bearing specifications. This situation is more common than you might think, especially in older equipment whose parts may be obsolete. If you’re searching for a solution in Wisconsin, and you’ve typed in “replacement bearing no specs Wisconsin,” you’re on the right path. Fusion Babbitting is here to help with expert bearing shop reverse engineering services that take the guesswork out of getting the right fit—fast and reliably.

Why It’s Critical to Get the Right Bearing Fit

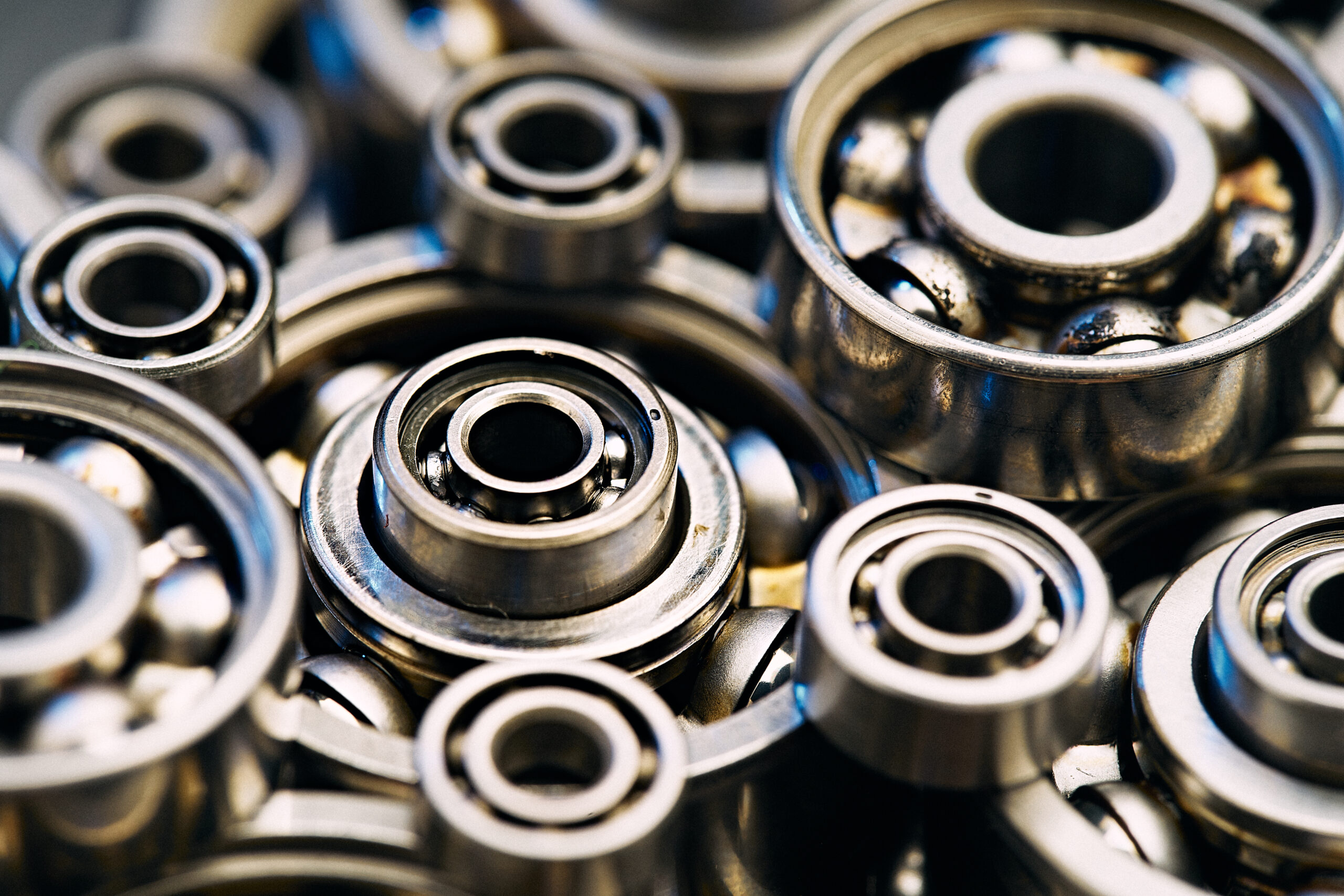

Bearings are the silent heroes in many mechanical systems—from pumps and turbines to electric motors and hydro power systems. Even the slightest mismatch can lead to severe wear, costly breakdowns, or even system failure. That’s why getting a precise replacement matters, even if you don’t have the original part number or blueprints at hand.

Improperly sized bearings cause vibration, overheating, and misalignment. These issues not only reduce efficiency but also damage adjacent components. That’s why replacing bearings without specs requires expertise, precision, and proven techniques—especially for mission-critical applications. Fusion Babbitting understands these needs and delivers dependable service designed to help your machinery run smoothly and safely.

When Specs Are Missing: Exploring Your Options

Option 1: Contact the Original Manufacturer

The first and most straightforward solution is reaching out to the OEM (Original Equipment Manufacturer). They may have records of your machine’s components, including detailed specs for the bearings. However, this isn’t always possible—especially if the equipment is old or the manufacturer is no longer in business. When that option falls short, specialized reverse engineering becomes your best bet.

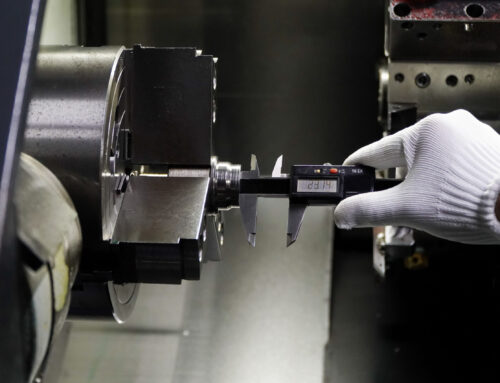

Option 2: Try Visual Identification and Measuring

If the old bearing is still intact (even if it’s worn or damaged), you can take some basic measurements like the inner diameter, outer diameter, and width. However, this method has its risks. Even tiny deviations can impact performance. Tolerances in bearing fitting are precise, and rough measuring tools may miss key differences. That’s why many maintenance professionals turn to a bearing shop that specializes in reverse engineering, such as Fusion Babbitting.

Option 3: Turn to a Professional Bearing Shop for Reverse Engineering

This is where Fusion Babbitting steps in. Based in Milwaukee, Wisconsin, Fusion Babbitting specializes in helping clients across the country replace bearings when specs are unavailable. Through our expert reverse engineering services, we recreate precise, effective bearing solutions—even when you’re working with outdated or broken components. Our team uses advanced technology to measure and replicate bearings accurately, saving you time, money, and future breakdowns.

How Fusion Babbitting Handles Bearing Shop Reverse Engineering

Fusion Babbitting has been serving customers since 1988, providing custom solutions for unique bearing challenges. When it comes to “replacement bearing no specs Wisconsin,” we’re proud to be the go-to source for service, precision, and fast turnaround. Here’s how we do it:

1. Physical Inspection

We begin with a thorough inspection of the component in question. Our experienced team assesses the worn or broken bearing to determine its geometry, material, and any signs of specific wear patterns. This step is crucial to understanding both the bearing’s function and potential points of weakness. We draw insights from scoring, heat discoloration, metallurgy, and housing fit to piece together the complete picture.

2. Measurements and Material Testing

Using precision equipment, we measure the bearing’s dimensions down to the micron. We also test the composition of the materials—especially important for applications involving high temperatures and loads, such as in paper mills, cement plants, or hydroelectric systems. Our lab-grade instruments and decades of experience help us choose materials that endure stress and time.

3. Create Detailed Drawings and Models

Next, our engineering team builds accurate manufacturing drawings and 3D models. These help us recreate the original component or improve upon it based on modern standards. Since we handle both the design and manufacturing in-house at our Milwaukee facility, we ensure full quality control from start to finish. Our CAD systems allow for revisions, archiving, and rapid production, reducing turnaround time significantly.

4. Custom Manufacturing

Fusion Babbitting doesn’t just fix bearings—we make them. Our team leverages advanced machining and centrifugal casting techniques to manufacture custom bearings that meet or exceed OEM standards. This is especially valuable for industries where downtime is costly, such as aluminum mills, fossil plants, and shipyards. We produce durable bearings that tackle harsh environments and high-performance demands.

5. Fusion Babbitting’s Signature Fusion Process

One of the top techniques we use in restoration and bearing rebuilding is Fusion Babbitting. This method ensures a stronger bond between the steel shell and the babbitt lining, enabling long service life and dependable performance. Fusion Babbitting creates consistent layers of babbitt material, eliminating hot spots and weak points. When applied using centrifugal casting or arc flame spraying, it results in bearings that are as good as—or often better than—the original.

The Fusion Babbitting Advantage

When you choose Fusion Babbitting, you’re not just getting a replacement—you’re getting expertise and high-quality workmanship. Here’s what sets us apart for those seeking “replacement bearing no specs Wisconsin” or reliable “bearing shop reverse engineering.”

In-House Capabilities

Our Milwaukee shop features everything from centrifugal casting to arc flame spray applications. We can machine parts up to 120 inches in length and diameter, meaning no task is too large or complex. Our skilled technicians and engineers handle all phases of evaluation, design, and production under one roof, saving time and ensuring accuracy. You’re dealing with one team, start to finish.

Emergency Services

We know emergencies don’t wait. That’s why we offer 24-hour emergency services for when the unexpected happens. Our team is always ready to serve your needs, day or night. Whether your facility is running 24/7 or responding to unexpected breakdowns, we’re only a phone call away. We also offer rush production timelines to get you back online fast.

Serving a Wide Range of Industries

Our experience spans numerous sectors:

– Aluminum mills

– Chemical and cement plants

– Paper mills

– Nuclear and fossil power plants

– Hydro and pump storage

– Shipyards and marine repair

– Motor repair shops

– Steel mills and mines

– Crushed stone and aggregate producers

Versatility in Applications

We regularly handle parts for electric motors, pumps, turbines, and hydro power systems. No matter the machine type, our reverse engineering helps get it running again quickly and efficiently. Our expertise in bearing repair and Fusion Babbitting gives our clients trusted solutions for both minor and major restoration projects.

What If The Bearing Is Completely Destroyed?

No bearing left to measure? Don’t worry. Our skilled team can work with nearby housing components or mating parts to reverse engineer the missing piece. We gather clues from surrounding measurements, wear marks, and housing tolerances to create a full profile of what’s needed. It’s like solving a puzzle—and our specialists are experts at it. Even remnants of old bearings can provide valuable information. With Fusion Babbitting’s technology and knowledge, reverse engineering is accurate even in complex or severely damaged cases.

What to Expect When You Contact Fusion Babbitting

When you reach out to us, we prioritize speed, service, and precision. Here’s what typically happens:

– You describe your equipment and problem

– If possible, you send us the old bearing or associated parts

– We inspect the parts and begin reverse engineering

– You receive drawings for approval

– We manufacture and ship the new bearing to your location

It’s a smooth, streamlined process designed to help you minimize downtime and maximize machine life. For clients across Wisconsin and the U.S., Fusion Babbitting is a trusted name in bearing replacement solutions. Our friendly staff guides you through the process, providing updates and answering questions along the way.

Why Clients Trust Fusion Babbitting

Fusion Babbitting brings over 40 years of combined technical experience. Our team is dedicated to providing reliable, efficient services tailored to industrial operations. From high-strength centrifugal castings to corrosion-resistant coating applications, everything we do aims to deliver long-lasting results for your equipment. Clients value our honesty, our precision, and our commitment to quality. Whether you need one replacement or a series of components made from scratch, we bring reliable solutions every time.

Fusion Babbitting’s Role in the Future

As industrial systems age and legacy equipment stays in use longer, reverse engineering and custom bearing manufacturing will continue to grow in importance. Fusion Babbitting remains at the forefront of this evolution by investing in new technology, ongoing staff training, and next-level customer service. Our Fusion Babbitting process keeps advancing too, helping us deliver even greater consistency and performance. We’re not just fixing past problems—we’re building future solutions.

Get Back Up and Running Today

If you’re searching for a solution to a replacement bearing with no specs in Wisconsin, stop worrying. Fusion Babbitting combines state-of-the-art reverse engineering with dependable manufacturing to solve even the trickiest bearing challenges. Our team serves both local Wisconsin businesses and clients across the country. From steel mills to marine applications, we build bearings that perform under pressure. Choosing Fusion Babbitting means choosing peace of mind, knowing your equipment is in expert hands.

We understand the urgency of downtime. That’s why we’re here to help—from first call to final delivery. Fusion Babbitting is your partner for dependable bearing services when precision matters most.

Contact Fusion Babbitting Today

Don’t waste precious time and resources trying to guess what your machine needs. Let the experts at Fusion Babbitting put you back in action with a custom-engineered solution that performs just like the original—if not better.

Fusion Babbitting Co., Inc.

4540 W. Burnham St., Milwaukee, WI 53219

Phone: 414.645.5800 | Toll-Free: 800.613.5118

Email: sales@fusionbabbitting.com

For all your bearing repair, rebuilding, and custom engineering needs, Fusion Babbitting is your trusted partner in Wisconsin and beyond. Whether you’re working with old, obsolete machinery or just need fast, reliable help, we’re ready with the experience and tools to get the job done right the first time. When everything depends on keeping your systems running, trust the proven experts in Fusion Babbitting and bearing shop reverse engineering.