Babbitt is a metal alloy that is white in color originally patented by Isaac Babbitt in 1839. Since then, the term babbitt has been adopted for other similar white metals made of copper, tin, antimony, and sometimes lead. Babbitt is used as a lubricant to ease friction and prevent corrosion.

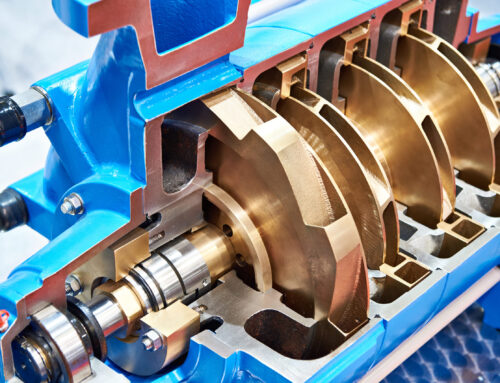

Babbitt is most commonly used on axles, bearings, and crankshafts. It can be applied to stronger metals such as cast iron, steel, and bronze as a low-friction lining. When it was first introduced it was primarily used for steam engines.

The combination of the hard metals (copper or antimony) and a soft (tin or lead) provides enough strength to handle the high speeds and still be lubricating to reduce friction. Tin alloy should be used with higher temperatures.

At Fusion Babbitting, we take pride in using high quality Babbitt to ensure you’re getting the best outcome for your bearings. We want to provide strong and lasting services. If you have questions about our specific processes, reach out to us today to join the Fusion Babbitting Nation wide family!