Fusion Babbitting: Revolutionizing Split Babbitt Bearings

In the world of industrial machinery, the longevity and efficiency of components are paramount. Among these, split babbitt bearings hold a special place. Known for their durability and reliability, these bearings are essential in various sectors, from manufacturing to energy production. This article delves into the importance of split babbitt bearings and babbitt parts, highlighting their benefits and offering insights into maintenance and selection.

Understanding the Basics of Split Babbitt Bearings

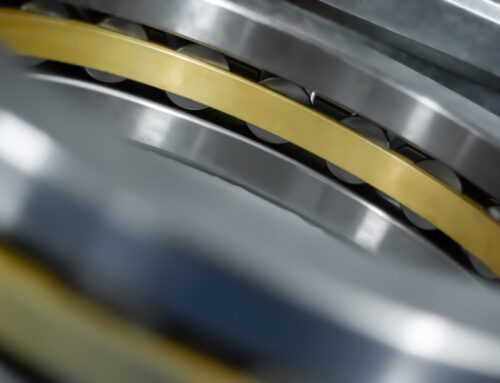

Split babbitt bearings are distinguished by their construction and material composition. They consist of a metal shell and a lining of babbitt metal, an alloy known for its softness and conformability. This unique combination offers superior wear resistance and adaptability, making these bearings ideal for heavy-duty applications. Their split design facilitates easy installation and maintenance, reducing downtime and enhancing productivity.

The Role of High-Quality Babbitt Parts

The performance of these babbitt bearings heavily relies on the quality of the babbitt parts. These components are critical for minimizing friction and wear, ensuring the machinery operates smoothly under various conditions. High-quality babbitt parts, crafted from carefully selected alloys, provide the durability and reliability that modern industries demand. It is essential to source these parts from reputable manufacturers to maintain the efficiency and longevity of your equipment.

Advantages of Babbitt Bearings

Split babbitt bearings offer numerous benefits, making them a preferred choice for many applications:

- Ease of Maintenance: Their split design allows for quick inspections and repairs without extensive dismantling.

- Versatility: They can accommodate a wide range of shaft sizes and loads, making them suitable for diverse machinery.

- Durability: High-quality babbitt linings ensure a long service life, even under harsh conditions.

- Efficiency: The low friction of babbitt bearings contributes to energy savings and improved machinery performance.

These advantages underscore the importance of selecting the right babbitt bearings and babbitt parts for your machinery.

Choosing the Right Provider for Split Babbitt Bearings

When it comes to bearings, partnering with the right provider is crucial. A reputable supplier offers not only high-quality products but also comprehensive support, from selection to maintenance advice. Look for providers with a track record of success in your industry and the technical expertise to recommend the best solutions for your specific needs.

Maintenance and Care for Longevity for Your Babbitt Bearings

Proper maintenance is key to maximizing the lifespan and performance of babbitt bearings. Regular inspections can identify wear and potential issues early, preventing costly downtime. Adequate lubrication, according to the manufacturer’s guidelines, is also critical. Attention to maintenance ensures that your machinery continues to operate efficiently, safeguarding your investment.

Modern Applications of Bearings

Split babbitt bearings find applications in a variety of settings, from electric motors to turbine engines. Their adaptability and resilience make them suitable for challenging environments, where reliability and performance are non-negotiable. By choosing the right bearings and ensuring their proper maintenance, businesses can achieve unparalleled efficiency and durability in their operations.

The Future of Bearings in Industry

As technology advances, the demand for more efficient and reliable machinery components grows. Bearings are evolving to meet these demands, with innovations in materials and design enhancing their performance and applications. The future of industrial machinery relies on components like these, which offer the perfect blend of tradition and innovation.

Bearings are a cornerstone of industrial machinery, offering unmatched durability, efficiency, and versatility. The key to leveraging these benefits is understanding the importance of quality babbitt parts and selecting the right bearings for your applications. With proper maintenance and care, bearings can significantly contribute to the performance and longevity of your machinery. As industries continue to evolve, the role of these bearings in ensuring operational efficiency and reliability will undoubtedly grow.