Understanding the Importance of Bearings in Industrial Equipment

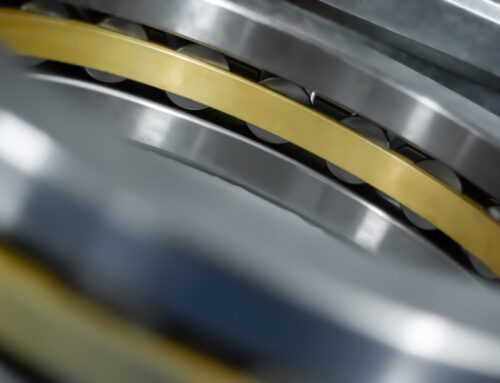

Industrial bearings play a crucial role in the functionality of heavy machinery. They reduce friction, support loads, and ensure smooth rotational movements in critical applications like electric motors, turbines, pumps, and hydro power systems. However, over time, bearings wear down due to friction, contamination, and operating conditions, leading to decreased efficiency or complete system failure.

When bearings show signs of wear, companies must decide whether to repair bearing issues, rebuild them, or fully replace them. This decision can impact operational costs, downtime, and overall equipment performance. Fusion Babbitting specializes in assessing and restoring industrial bearings, helping businesses maintain reliable equipment operation with expert repair and rebuilding services.

Signs Your Bearings Need Repair or Replacement

Unusual Noises and Vibrations

One of the first indicators of bearing deterioration is unusual noise or excessive vibration. Bearings should operate smoothly, producing minimal sound. If your equipment emits grinding, clicking, or rumbling noises, it may indicate worn-out surfaces, misalignment, or uneven wear. Fusion Babbitting offers precision machining and rebabbitting services to restore bearings to optimal condition, ensuring quiet and efficient operation.

Excessive Heat Build-Up

Overheating is another serious sign of bearing failure. When bearings lose lubrication or experience increased friction due to wear, they generate excessive heat. This can lead to metal expansion, further reducing efficiency and increasing the risk of breakdowns. If your bearings are running hotter than usual, evaluating whether to repair bearing systems or replace them is critical to preventing unexpected failures.

Visible Wear and Surface Damage

Inspect bearings regularly for visible signs of wear, such as pitting, scoring, or cracks. Damaged surfaces affect load distribution and reduce bearing lifespan. If minor damage is present, repair solutions like centrifugal casting or flame spray application from Fusion Babbitting can restore the bearings. However, severe structural damage may require full replacement.

Frequent Lubrication Issues

If your bearings require constant re-lubrication or show signs of lubricant contamination, it can indicate internal damage. Poor lubrication can lead to increased wear, overheating, and failure. Addressing lubrication-related failures through timely repairs can extend the lifespan of your bearings and reduce ongoing maintenance costs.

Factors to Consider When Deciding Between Bearing Repair or Replacement

Cost Comparison: Repair vs. Replacement

One of the key factors when deciding whether to repair bearing systems or replace them is cost. Full replacement can be expensive, especially for large industrial bearings or those with complex designs. Repairing or rebabbitting worn bearings with Fusion Babbitting’s specialized services often proves more cost-effective, restoring functionality without the expense of sourcing new components.

Downtime and Operational Impact

Replacing a bearing may require sourcing a new component, which can lead to extended downtime if the part is not readily available. Repairing an existing bearing is often quicker, especially with emergency services like those offered by Fusion Babbitting. Minimizing downtime is crucial for industries like aluminum mills, paper mills, and cement plants, where continuous operation is essential.

OEM Specifications and Performance Standards

Industrial bearings must consistently meet OEM performance standards to ensure reliability and efficiency. Fusion Babbitting specializes in bearing rebuilding and customization, ensuring repairs not only restore bearings but also enhance durability and strength, often exceeding original specifications.

Obsolete or Hard-to-Find Bearings

For older machinery, finding replacement bearings can be challenging. Reverse engineering services, such as those provided by Fusion Babbitting, allow for the recreation of obsolete bearings, ensuring continued equipment operation without requiring expensive system upgrades.

The Fusion Babbitting Approach to Bearing Repair and Restoration

Rebabbitting and Rebuilding Process

Fusion Babbitting offers comprehensive rebabbitting services using centrifugal casting technology. This method ensures optimal bond strength and durability, restoring worn bearings to like-new condition. By precisely applying new Babbitt material and machining bearings back to specifications, repaired bearings function with the same efficiency as new components.

Advanced Arc Flame Spray Technology

In cases where bearing housings, shafts, or other components sustain wear, Fusion Babbitting utilizes advanced arc flame spray applications to restore dimensions. This process involves applying metal coatings to worn surfaces, followed by precision machining to meet original tolerances.

Custom Bearing Manufacturing

For clients who need specialized or entirely new bearings, Fusion Babbitting offers expert custom manufacturing. With the capability to produce high-precision bearings up to 120 inches in diameter, the company ensures that even the most complex bearing designs can be fabricated with accuracy.

Industries That Benefit from Bearing Repair Services

Fusion Babbitting serves a wide range of industries that rely on heavy-duty bearings for continuous operations:

– Aluminum Mills: Bearings in aluminum processing machinery must withstand high temperatures and heavy loads.

– Cement & Chemical Plants: Industrial mixers and rotating equipment require strong, wear-resistant bearings.

– Power Plants: Bearings in turbines and hydroelectric generators require precise maintenance for reliable energy production.

– Marine Repair & Shipyards: Pumps, propellers, and rotating components rely on properly maintained bearings.

– Mining & Steel Mills: Harsh conditions demand hardened bearings that resist dust, debris, and extreme pressure.

– Paper Mills: High-speed rollers rely on accurately machined bearings to maintain production efficiency.

The Long-Term Benefits of Bearing Repair

Beyond immediate cost savings, opting for bearing repair offers long-term advantages. Investing in professional rebuilding services like those provided by Fusion Babbitting extends the lifespan of existing equipment and reduces waste associated with full replacements. This not only benefits your budget but also supports sustainability efforts by minimizing industrial waste and resource consumption.

Additionally, maintaining or restoring bearings through expert services prevents further damage to connected machinery components. Excessive vibration, misalignment, or rough operation caused by damaged bearings can lead to premature wear on other parts of the system, increasing overall maintenance expenses. Repairing bearings on time helps avoid extensive equipment overhauls down the line.

Enhanced Equipment Reliability

Well-maintained bearings directly contribute to improved equipment reliability. When bearings are properly repaired and maintained, machinery operates more smoothly, reducing the likelihood of sudden breakdowns. Fusion Babbitting’s precision repair techniques ensure that industrial bearings function correctly, decreasing the risk of unexpected production halts.

Optimized Bearing Performance

High-performance bearings are essential for industrial applications requiring continuous rotation under heavy loads. Fusion Babbitting ensures that repaired bearings meet or exceed original manufacturer performance standards. Their state-of-the-art machining techniques restore integrity, providing dynamically balanced bearings that improve efficiency and extend service life.

Making the Best Decision for Your Bearings

Deciding whether to repair bearing components or replace them requires evaluating multiple factors, including cost, downtime, and availability. While replacing bearings might seem like the easiest solution, repairing them through professional services like Fusion Babbitting can save businesses time and money while extending the lifespan of machinery.

Fusion Babbitting’s expert team provides high-quality bearing repair and maintenance solutions, ensuring that industries relying on heavy-duty bearings can continue operating without unnecessary disruptions. By utilizing advanced technology, reverse engineering, and custom manufacturing, they help businesses keep their equipment running efficiently.

Contact Fusion Babbitting for Expert Bearing Solutions

If you need assistance determining whether to repair, rebuild, or replace your industrial bearings, Fusion Babbitting is here to help. Their experienced team provides precision repairs, rapid turnaround times, and high-quality results.

Contact Fusion Babbitting today:

– Address: 4540 W. Burnham St., Milwaukee, WI 53219

– Phone: 414.645.5800 | Toll-Free: 800.613.5118

– Email: sales@fusionbabbitting.com

Ensure your industrial bearings remain in peak condition with expert repair and maintenance services from Fusion Babbitting. Reach out now and keep your operations running smoothly!