Heavy Machinery Bearing Maintenance: Essential Tips and Services

When it comes to keeping heavy machinery running smoothly, bearing maintenance is crucial. At Fusion Babbitting Co., Inc., we specialize in providing top-notch heavy machinery bearing maintenance and machine bearing services. With over 40 years of experience, we ensure that your equipment performs at its best, minimizing downtime and maximizing efficiency. In this blog, we’ll explore the importance of bearing maintenance and the comprehensive services we offer to keep your machinery in optimal condition.

Why Heavy Machinery Bearing Maintenance Matters

Heavy machinery operates under extreme conditions, often handling significant loads and high speeds. Bearings in these machines are critical components that reduce friction and wear, ensuring smooth operation. Regular maintenance of these bearings is essential to prevent failures that can lead to costly repairs and prolonged downtime. Proper maintenance not only extends the lifespan of the bearings but also enhances the overall performance of the machinery.

Key Benefits of Regular Bearing Maintenance

- Increased Equipment Lifespan: Regular maintenance helps prevent premature bearing failure, extending the life of your machinery.

- Enhanced Performance: Well-maintained bearings ensure smoother operation, reducing friction and wear.

- Cost Savings: Preventative maintenance reduces the likelihood of major breakdowns, saving money on repairs and replacements.

- Reduced Downtime: Keeping bearings in good condition minimizes the risk of unexpected failures, ensuring continuous operation.

Comprehensive Bearing Services at Fusion Babbitting

At Fusion Babbitting, we offer a full range of bearing services to meet your heavy machinery needs. Our team of experts uses the latest technology and techniques to provide high-quality maintenance and repair services. Let’s take a closer look at some of the key services we offer.

Repair, Rebabbitting, and Rebuilding Services

Our repair and rebabbitting services are designed to restore your bearings to their original condition. We take great pride in our ability to repair and rebuild bearings to meet or exceed OEM specifications. Our technicians thoroughly inspect each bearing, using ultrasonic testing and other advanced methods to ensure top quality.

Centrifugal Casting and ReBabbitting

Centrifugal casting is a vital part of our rebabbitting process. This technique ensures high bond strength and bearing integrity, resulting in long-lasting performance. We maintain an inventory of certified babbitt, allowing us to match any OEM specification your bearing may require.

Arc Flame Spray Application

For worn components, our arc flame spray application is an effective solution. This process builds up the metal coating on the bearing’s outside diameter and housings. The new coating is then machined to original OEM specifications, restoring the component to like-new condition.

Reverse Engineering of Bearings

When original drawings or specifications are unavailable, our reverse engineering services come into play. We can create new bearing components that meet or exceed OEM specifications. This service is crucial for maintaining older machinery or custom equipment where parts are no longer readily available.

Ensuring Reliable Machine Bearing Services in Your Area

Finding reliable machine bearing services in your area can be challenging, but Fusion Babbitting makes it easy. Our Midwest-based facility serves clients across the U.S., providing top-quality bearing services wherever you are located. Here’s how we ensure our services meet your needs:

General Fabrication and Machining

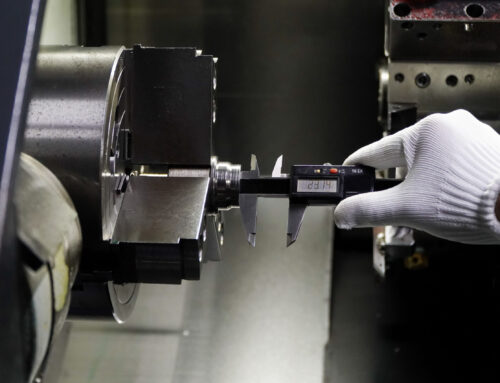

Our state-of-the-art machine shop is capable of handling a wide range of fabrication and machining tasks. We can machine bearings and other components up to 120 inches in diameter and length, ensuring precision and accuracy in every job.

New Manufacturing Services

In addition to repair and maintenance, we also offer new manufacturing services. If you need custom bearing products manufactured to precise specifications, we can help. Our team works with many major OEM manufacturers to deliver high-precision components on time.

Nationwide Service and Support

Located in the Midwest, our manufacturing and rebuilding facility is equipped to serve clients across the U.S. We provide nationwide service and support, ensuring that you have access to the best bearing services no matter where you are located.

Trust Fusion Babbitting for Your Bearing Needs

Choosing the right partner for heavy machinery bearing maintenance is essential for the success of your operations. Fusion Babbitting is committed to providing the highest quality services to keep your machinery running smoothly. Here are a few reasons why our clients trust us:

- Expertise: Our team has over 40 years of combined experience in bearing maintenance and repair.

- Quality: We use the latest equipment and techniques to ensure that every bearing we work on meets or exceeds OEM specifications.

- Reliability: We offer a personal guarantee that your rebuilt bearings will be as good as, or even better than new.

- Nationwide Service: No matter where you are in the U.S., we can provide the bearing services you need.

Our Personal Guarantee

At Fusion Babbitting, we stand behind the quality of our work. Every bearing we rebuild undergoes thorough inspection, including ultrasonic testing and babbitt certifications. We guarantee that your rebuilt bearings will meet or exceed the quality of new bearings, giving you peace of mind and reliable performance.

The Process of Heavy Machinery Bearing Maintenance

Understanding the maintenance process can help you appreciate the level of expertise and precision involved. Here’s a step-by-step overview of our process:

- Initial Consultation: We discuss your specific needs and gather all necessary information to create a custom maintenance plan.

- Inspection and Assessment: Our technicians inspect the bearings, using advanced testing methods to assess their condition.

- Repair and Rebuilding: Depending on the assessment, we perform the necessary repairs, rebabbitting, or rebuilding to restore the bearings.

- Centrifugal Casting: For rebabbitting, we use centrifugal casting to ensure a strong bond and high integrity.

- Machining and Finishing: The bearings are machined to precise tolerances, ensuring optimal performance.

- Final Inspection: Each bearing undergoes a final inspection to ensure it meets or exceeds OEM specifications.

- Delivery and Support: The finished bearings are delivered to your location, and we provide ongoing support to ensure they perform as expected.

Contact Fusion Babbitting for Heavy Machinery Bearing Maintenance

If you are looking for reliable and high-quality heavy machinery bearing maintenance, look no further than Fusion Babbitting Co., Inc. Our team is ready to provide you with the best solutions for your specific needs. Contact us today to learn more about our services and how we can help you keep your machinery running smoothly.

Ready to improve your machinery’s performance with expert bearing maintenance? Contact Fusion Babbitting Co., Inc. today to discuss your needs and get started on your custom maintenance plan. Our team of experts is here to help you achieve reliable and efficient operations. Don’t wait – reach out now!