Why Custom Thrust Bearings Matter in Industrial Machinery

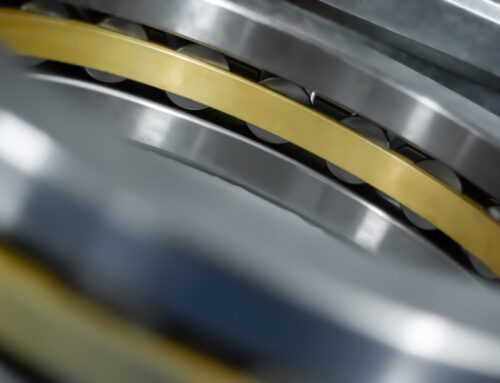

When your equipment operates under high pressure and axial loads, a thrust bearing plays a critical role in keeping everything running smoothly. These bearings are designed to handle force along the axis of a rotating shaft—something common in turbines, pumps, motors, and other heavy-duty machinery. But off-the-shelf options don’t always fit the bill. That’s where custom thrust bearing solutions come into play.

If you’re in Wisconsin or anywhere in the U.S. looking for high-quality, tailor-made thrust bearings, Fusion Babbitting is a name you can trust. With a legacy dating back to 1988, this Milwaukee-based company has been a reliable provider for industrial bearing manufacturing WI businesses rely on.

Fusion Babbitting: A Leader in Custom Thrust Bearings

Decades of Expertise and Dedication

Fusion Babbitting Co., Inc. has been shaping the future of industrial bearings for more than three decades. Located at 4540 W. Burnham St. in Milwaukee, Wisconsin, they’ve built a reputation for precision, quality, and unmatched customer service. Whether you’re in mining, marine repair, or energy production, Fusion Babbitting has the experience to meet your exact needs for a custom thrust bearing Wisconsin project.

Specialized Services Tailored to Your Equipment

When your operation can’t afford downtime, Fusion Babbitting’s custom services are essential. They go beyond simple machining to offer a full suite of services:

– Repair, rebabbitting, and rebuilding of bearings to meet or exceed OEM standards

– Centrifugal casting using certified Babbitt materials for strong, durable bonds

– Arc flame spray applications to restore worn surfaces and bring components back to factory specs

– Reverse engineering to recreate parts that are no longer manufactured

– General fabrication and machining for parts up to 120 inches in diameter and length

– New custom manufacturing of high-precision thrust bearings for unique applications

Fusion Babbitting provides everything from inspection to final installation, making it easier to get a custom thrust bearing you can rely on.

What to Look for in a Custom Thrust Bearing Manufacturer

Proven Track Record with Diverse Industries

When choosing a provider for custom thrust bearings, experience across multiple sectors is key. The team at Fusion Babbitting has provided solutions to clients in industries including:

– Aluminum mills

– Cement and chemical plants

– Fossil and nuclear power plants

– Hydropower and pump storage systems

– Mines and steel mills

– Motor repair shops

– Paper mills

– Shipyards and marine repair centers

– Crushed stone and aggregate production

This wide industry knowledge helps the company understand and anticipate unique challenges you might face in your machinery, ensuring better performance and longer equipment life.

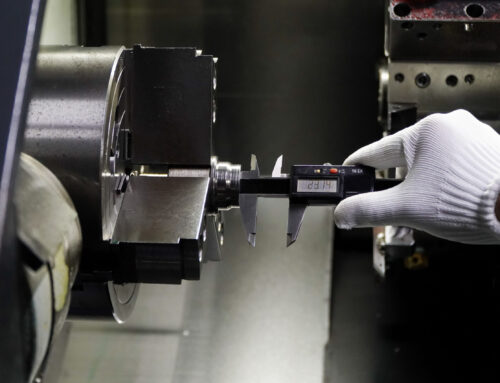

Advanced Technology and Skilled Craftsmanship

Industrial bearing manufacturing WI solutions require more than just tools—they need human expertise. Fusion Babbitting combines cutting-edge machinery with a team of skilled technicians. Together, they produce precision-engineered thrust bearings that meet strict quality standards. Whether your needs are high-speed or heavy-load applications, they deliver reliable results.

Emergency Services for Urgent Bearing Repairs

Some equipment just can’t wait. That’s why Fusion Babbitting offers 24-hour emergency service. If your production line or critical system is down, their expert team can act fast to assess the damage and get a solution in motion. It’s another reason why customers across the country rely on Fusion Babbitting for their most urgent repair and replacement needs.

How Fusion Babbitting Builds Custom Thrust Bearings

Step 1: Engineering Assessment

Before anything is manufactured, Fusion Babbitting takes a close look at the equipment and application. They assess operational loads, temperatures, motion patterns, and wear factors. Whether it’s for a hydro power turbine or an electric motor, the design must reflect your actual operating environment. This ensures the custom thrust bearing is built to exact specifications.

Step 2: Reverse Engineering if Needed

If you can’t provide an original specification or part drawing, the company can reverse-engineer the existing bearing. Using state-of-the-art tools, they measure, scan, and model each detail before producing new blueprints. This is especially useful for obsolete parts or older equipment where replacements are no longer available.

Step 3: Fabrication Using High-Quality Materials

Once the design is finalized, fabrication begins. Certified Babbitt alloys ensure bearings have excellent conformability and embeddability, critical for high-load applications. The centrifugal casting method ensures a strong bond between the Babbitt layer and the base, reducing the chances of separation or failure under pressure.

Step 4: Machining and Testing

Next, the team machines the thrust bearing to exact dimensions. They use high-precision lathes and mills to guarantee a perfect fit. After that, the bearing is tested to confirm alignment, integrity, and performance. Everything is double-checked before shipment to ensure reliability.

Applications for Custom Thrust Bearings

Fusion Babbitting’s bearings are used in some of the most demanding environments in America. Their products are built to thrive in:

– Electric motors running at high RPMs

– Hydro power plants where water flow creates constant axial force

– Pumps dealing with fluid pressure across many industries

– Turbines exposed to heat and heavy vibration

Because their bearings are custom-made, they fit seamlessly into your equipment, reducing wear and extending service life.

Understanding the Importance of Fusion Babbitting

At the heart of Fusion Babbitting’s expertise is the babbitting process itself. Babbitting is a key technique in bearing manufacturing, where a soft metal layer—known as Babbitt—is bonded to a stronger backing shell. This method allows for the necessary give and lubrication during high-load operation. Fusion Babbitting uses advanced centrifugal casting and metal spraying processes to apply Babbitt alloys in a controlled and precise manner.

Fusion Babbitting goes a step further by inspecting each babbitted layer for bond strength, consistency, and thickness. The expertise in both the fusion of Babbitt to the backing and in adjusting alloy composition ensures bearings can handle the specific demands of your equipment. Fusion Babbitting isn’t just their name—it’s their core strength that sets them apart in the world of industrial bearing manufacturing WI customers count on.

Why Choose Fusion Babbitting for Custom Thrust Bearing Wisconsin Services

Local Service, National Reach

While headquartered in Milwaukee, Fusion Babbitting serves clients nationwide. Their streamlined process means your custom thrust bearing can be designed, manufactured, shipped, and installed with minimal delay, regardless of your location. Being centrally located in Wisconsin also means fast lead times for Midwest customers.

Decades of Proven Results

Fusion Babbitting has been trusted since 1988 for one reason: performance. They’ve consistently delivered top-quality bearings that outlast OEM components and drive better machine performance. Their focus on long-term client satisfaction and a no-shortcuts approach to repair and manufacturing make them a reliable partner.

One-Stop Shop for Industrial Bearing Manufacturing WI Needs

Rather than juggling multiple vendors, work with a company that handles everything from reverse-engineering to final assembly. Fusion Babbitting is more than a machine shop—they’re a complete bearing technology provider. Whether you’re updating an aging plant or outfitting a new system, they provide a strategic advantage that goes beyond part fabrication.

Get in Touch with Fusion Babbitting

If your operation needs a custom thrust bearing Wisconsin business owners count on, go with the experts at Fusion Babbitting. They offer fast turnaround times, precision engineering, and helpful customer service. No matter how rare the part or complex the job, Fusion Babbitting has the tools and talent to get it done right the first time.

Contact them today at 414.645.5800 or toll-free at 800.613.5118. You can also email sales@fusionbabbitting.com for more information on your custom thrust bearing needs. Their team is always ready to walk you through the design and manufacturing process.

Located at 4540 W. Burnham St., Milwaukee, WI 53219, Fusion Babbitting stands out as a trusted name in industrial bearing manufacturing WI industries rely on. Don’t leave your machinery’s performance to chance—partner with Fusion Babbitting for lasting, custom-built solutions that keep your equipment moving.