Introduction to Bearings: Understanding the Basics

When it comes to industrial machinery, bearings are essential components that ensure efficient and reliable operation. They reduce friction, facilitate rotational movement, and help machinery handle significant loads. However, selecting the right type of bearing—whether a Babbitt bearing or a roller bearing—can be challenging. Each type offers distinct features and benefits tailored to specific operational requirements. At Fusion Babbitting, we are experts in high-quality Babbitt bearing services and can guide you in making the best decision for your equipment.

What Are Babbitt Bearings?

Babbitt bearings are a type of journal bearing made from Babbitt metal, a soft alloy commonly composed of tin, lead, copper, and antimony. Known for their exceptional load-bearing capabilities, Babbitt bearings excel at reducing friction while allowing for some level of misalignment in machinery. What makes them unique is their ability to embed debris into the soft metal, preventing damage to other critical machine parts. This feature enhances their durability and makes them highly valuable across multiple industries.

Key Features of Babbitt Bearings

Babbitt bearings are synonymous with long-lasting performance and unparalleled repairability. Unlike roller bearings, they can be restored through the process of rebabbitting, which involves applying a fresh layer of Babbitt material to rejuvenate the bearing. This repair method greatly extends the lifespan of the component. At Fusion Babbitting, we’ve been committed to providing rebabbitting services since 1988, combining certified materials with advanced techniques like centrifugal casting to deliver optimal results. These features make Babbitt bearings an excellent choice for machinery exposed to harsh conditions or heavy loads.

What Are Roller Bearings?

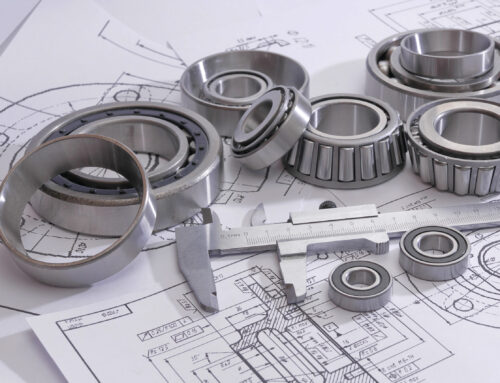

Roller bearings utilize rolling elements such as cylinders, balls, or tapered rollers to minimize friction and enable smooth rotational motion. These bearings are often used in high-speed applications and are available in a variety of configurations, including cylindrical, tapered, and spherical designs. Roller bearings are appreciated for their precision, ease of installation, and capacity to handle both radial and axial loads without sacrificing efficiency.

Key Features of Roller Bearings

The appeal of roller bearings lies in their ability to maintain consistent performance at high speeds. They are also designed to meet the demands of moderate load conditions with minimal required maintenance. However, they are less durable under extreme loads, contaminants, or misalignment when compared to Babbitt bearings. In situations involving significant wear or damage, roller bearings often have to be replaced entirely—a process that can be more expensive and labor-intensive than repairing a Babbitt bearing.

Babbitt Bearings vs Roller Bearings: A Detailed Comparison

Durability and Longevity

When it comes to durability, Babbitt bearings have the upper hand, particularly in applications that involve high loads and low speeds. Their ability to embed contaminants ensures that machine components remain protected, even under challenging conditions. Meanwhile, roller bearings, while robust, can suffer from damage due to debris or misalignment over time. This makes them less suitable for highly demanding environments.

Repair and Maintenance

Babbitt bearings are known for their cost-effectiveness in terms of repair. Through services such as rebabbitting, offered by Fusion Babbitting, worn or damaged bearings can be restored to their original functionality without requiring complete replacement. Roller bearings, on the other hand, typically necessitate full replacement once they fail, leading to higher costs and potential downtime for machinery.

Performance in High-Speed Applications

For machinery that operates at high speeds, roller bearings are often the preferred choice. Their rolling elements ensure smooth and consistent performance at rapid rotation. However, for equipment running in low- to moderate-speed environments, where load-carrying capacities and shock absorption matter, Babbitt bearings excel.

Load Capacity

Babbitt bearings are unmatched in their ability to handle heavy loads, often making them indispensable in industries such as steel mills, power plants, and marine applications. Though roller bearings are efficient in many scenarios, they usually fall short when it comes to supporting extreme load conditions. As a result, Babbitt bearings become the superior option in heavy-duty environments.

Industries and Applications

Where Are Babbitt Bearings Used?

Babbitt bearings serve as a backbone in industries that demand durability under heavy loads and adverse conditions. Fusion Babbitting caters to sectors including aluminum mills, shipyards, cement plants, and hydro power systems. Applications range from turbines and pumps to electric motors and industrial machinery. The resilience and flexibility of these bearings make them indispensable in maintaining operational efficiency across various industries.

Where Are Roller Bearings Used?

Roller bearings find their place in industries that prioritize high-speed operation and precision. Automotive manufacturing, aerospace engineering, and robotics are some prime examples where such bearings are commonly deployed. While ideal for fast-moving machinery and moderate loads, their lower capacity for heavy-duty applications limits their usage in industries like steel or paper manufacturing.

Choosing the Right Bearing for Your Equipment

The decision between Babbitt bearings and roller bearings depends heavily on your equipment’s unique operating conditions. For machinery exposed to heavy loads, frequent misalignment, or harsh environments, Babbitt bearings are the obvious choice. Fusion Babbitting offers custom solutions for Babbitt bearings, providing both repair and new manufacturing services to meet the specific needs of your machinery.

On the other hand, if your machinery prioritizes speed and precision over load capacity, roller bearings could be the better fit. However, it’s important to factor in the long-term costs, as complete replacement of roller bearings can outweigh the benefits for some industries. Consulting with experts like those at Fusion Babbitting can help you make an informed decision that aligns with your operational goals.

Why Choose Fusion Babbitting for Your Bearing Needs?

Based in Milwaukee, WI, Fusion Babbitting has been a pioneer in delivering premium bearing solutions for over four decades. Our services extend beyond just repair and rebabbitting; we also specialize in reverse engineering, rebuilding, centrifugal casting, and new manufacturing of custom bearings tailored to meet OEM specifications. Utilizing advanced technologies and certified materials, we ensure that all bearings meet or exceed performance expectations.

Our expertise spans across industries, serving clients in paper mills, marine repair, fossil power plants, aluminum mills, and more. Whether you require repairs for worn-out bearings or need precision-crafted custom solutions, Fusion Babbitting is equipped to handle it all. By partnering with us, you gain access to a combination of industry knowledge, cutting-edge technology, and unparalleled customer support.

Conclusion

The choice between Babbitt bearings and roller bearings is critical to ensuring optimal performance and longevity for your machinery. While Babbitt bearings excel in heavy-duty applications, roller bearings are more suited to high-speed, precision environments. Understanding the specific demands of your equipment and operational conditions will help you make the right decision.

At Fusion Babbitting, we are committed to delivering high-quality Babbitt bearing solutions that meet the exact needs of your industry. Whether you require repair, rebabbitting, or new custom manufacturing, our team is ready to assist you. Contact Fusion Babbitting today to experience industry-leading expertise and solutions tailored to enhance your equipment’s longevity and efficiency.