Understanding Babbitt Bearing Failure

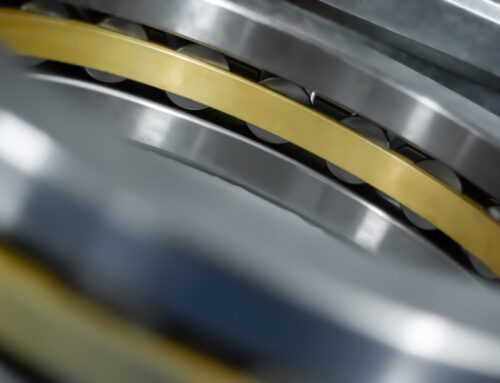

Babbitt bearings play a critical role in the smooth operation of industrial machinery. However, problems like babbitt cracking and delamination can lead to significant issues if not addressed promptly. At Fusion Babbitting, we understand the importance of effective babbitt bearing failure analysis to ensure your equipment runs smoothly and efficiently. Performing a thorough analysis helps prevent further damage, reduces downtime, and saves on costly repairs.

What Causes Babbitt Cracking?

Cracking in babbitt bearings is typically caused by excessive loads, poor lubrication, or improper installation.

– Excessive load: Bearings might experience stress beyond their design limits, causing the babbitt to crack.

– Poor lubrication: Without adequate lubrication, frictional heat increases, leading to babbitt deterioration and eventual cracking.

– Improper installation: Incorrect installation or alignment issues can unevenly distribute loads, causing stress concentrations that result in cracks.

Delamination Delve: Causes and Consequences

Delamination occurs when layers of the babbitt lining separate from the bearing surface. Common causes include incompatible materials, contamination, and inadequate adhesion.

– Incompatible materials: Using incompatible backing or babbitt materials can lead to separation under stress.

– Contamination: The presence of foreign particles can weaken the babbitt matrix.

– Inadequate adhesion: Poor bonding techniques during manufacturing or repair can leave the babbitt susceptible to delamination. Without prompt attention, delamination can accelerate wear and cause machine failures, leading to expensive overhauls.

The Role of Fusion Babbitting in Bearing Failure Analysis

Fusion Babbitting, established in 1988 and located in Milwaukee, WI, is a leader in babbitt bearing services. With over 40 years of combined expertise, we specialize in repair, rebabbitting, rebuilding, reverse engineering, and custom manufacturing. We provide solutions that meet or exceed OEM specifications, ensuring the highest performance standards for your equipment.

Repair, Rebabbitting, and Rebuilding

To address babbitt cracking and delamination, our skilled specialists at Fusion Babbitting offer high-quality repairs. We ensure each bearing meets or exceeds OEM standards, prolonging life and enhancing performance.

Centrifugal Casting: A Vital Process

Through centrifugal casting, we ensure robust bond strength and bearing integrity using certified babbitt materials. This process is crucial for preventing future babbitt failures and extending the lifespan of your machinery.

Arc Flame Spray Application

Our advanced arc flame spray application restores worn components by machining them back to their original specifications. This technique is ideal for repairing bearings experiencing wear and tear.

Advanced Techniques in Bearing Restoration

Fusion Babbitting utilizes a variety of advanced techniques to restore bearings to peak condition. Beyond centrifugal casting and arc flame spray, we employ specialized thermal treatments and precision machining to ensure the longevity and reliability of your equipment. These processes not only improve performance but also add years of functional life to your machinery, reducing the need for frequent replacements.

How Fusion Babbitting Protects Your Assets

With our comprehensive services, Fusion Babbitting protects your machinery from potential failures. Our specialists analyze bearings to identify signs of cracking or delamination early, ensuring issues are remedied before escalating.

Reverse Engineering for Obsolete Parts

When obsolete bearings require replacement, our reverse engineering service creates precise replicas. We use detailed drawings and advanced equipment to manufacture components that perfectly fit and function like the originals.

Fabrication and New Manufacturing

For components up to 120 inches in diameter and length, Fusion Babbitting handles general fabrication and machining. We also produce high-precision custom bearing products for OEMs, guaranteeing top-quality parts that maintain optimal machinery function.

Comprehensive Support and Consultation

Fusion Babbitting not only offers technical services but also provides comprehensive support and consultation. Our experienced team is available to advise on maintenance best practices and the latest industry developments, helping clients keep up with technological advancements and market demands. By prioritizing collaboration and information sharing, we aim to empower our clients to make informed decisions about their equipment investments.

Industry Applications of Our Expertise

Fusion Babbitting serves a diverse range of industries, ensuring machines across various fields operate efficiently.

– Aluminum Mills

– Cement & Chemical Plants

– Fossil & Nuclear Plants

– Hydro/Pump Storage

– Marine Repair

Our expertise is also valuable in industries like:

– Mines & Steel Mills

– Motor Repair Shops

– Paper Mills

– Shipyards

– Crushed Stone Producers

Specific Applications in Equipment

Our services are designed to meet the needs of various equipment such as:

– Electric Motors

– Hydro Power Systems

– Pumps

– Turbines

Expanding Horizons with Innovative Solutions

Fusion Babbitting continually explores innovative solutions to better meet the evolving needs of its clients. By investing in research and development, we aim to expand our capabilities and offer next-generation solutions that address the unique challenges faced by different industries. Whether it’s incorporating automation or adapting to green technologies, Fusion Babbitting is committed to setting new standards in the field of babbitt bearing services.

About Fusion Babbitting

With a commitment to superior service and quality, Fusion Babbitting focuses on advanced solutions for improving the performance and longevity of industrial bearings. Our specialists leverage their experience and cutting-edge technology to deliver results that clients can depend on. For emergencies, we offer 24-hour emergency services to minimize downtimes for clients across the nation.

If you are experiencing babbitt bearing issues or simply want to ensure optimal performance, contact Fusion Babbitting. We’re located at 4540 W. Burnham St., Milwaukee, WI 53219. Reach out via phone at 414.645.5800 or toll-free at 800.613.5118. You can also send us an email at sales@fusionbabbitting.com.

Securing Longevity for Your Machinery

Addressing babbitt bearing issues like cracking and delamination is crucial for maintaining the efficiency and reliability of your machinery. Fusion Babbitting is dedicated to providing exceptional babbitt bearing failure analysis and repair services to help you avoid costly repairs and downtime. Ensure your equipment operates at its peak by partnering with Fusion Babbitting, industry leaders in extending the life and performance of your machinery. By entrusting your babbitt bearing needs to us, you’re investing in the future reliability and efficiency of your operations. At Fusion Babbitting, we strive to deliver not just services, but peace of mind, knowing that your machinery is in capable and expert hands, ready to perform at its best now and into the future.