Fusion Babbitting: Revolutionizing with the Arc Spraying Process

Elevating Industrial Components through Arc Spraying

The arc spraying process stands at the forefront of surface engineering technologies, offering a versatile solution for enhancing the durability and performance of industrial components. This innovative technique involves using an electric arc to melt feedstock material, typically in wire form, which is then atomized and propelled onto a substrate to form a cohesive coating. Fusion Babbitting specializes in this advanced process, delivering unparalleled quality and durability to a wide array of industrial applications. Our commitment to excellence ensures that each project benefits from a tailored approach, maximizing the lifespan and efficiency of critical machinery parts.

The Significance of Arc Spraying in Industry

Arc spraying plays a pivotal role in modern manufacturing and maintenance processes, offering a cost-effective method for extending the service life of components. This process is not only about applying protective coatings but also about restoring surfaces, improving wear resistance, and enhancing part performance. Industries ranging from aerospace to energy production rely on the arc spraying process for its quick application and exceptional bond strength. Fusion Babbitting leverages this technology to provide solutions that meet the stringent demands of industrial operations.

Key Benefits of the Arc Spraying Process

The arc spraying process offers a multitude of advantages for industrial applications:

- Extended Component Life: Coatings applied through arc spraying significantly increase the wear resistance of parts.

- Cost Efficiency: Reducing the need for frequent replacements and repairs, arc spraying is a cost-saving solution for many industries.

- Versatility: Capable of applying a wide range of materials to various substrates, arc spraying accommodates diverse application needs.

- Rapid Application: Fast processing times minimize downtime, allowing for quicker turnaround in maintenance and repair operations.

These benefits underscore the value of integrating the arc spraying process into maintenance and manufacturing strategies.

Fusion Babbitting’s Expertise in Arc Spraying

At Fusion Babbitting, our proficiency in the arc spraying process sets us apart. Our technicians are highly trained and experienced, ensuring that every application meets the highest standards of quality and performance. We understand the critical nature of industrial components and employ a meticulous approach to every project, from preparation to the final coating application. Our commitment to innovation and quality makes us a leader in arc spraying services, trusted by industries across the board.

Applications and Industries Benefiting from Arc Spraying

The versatility of the arc spraying process makes it suitable for a wide range of applications:

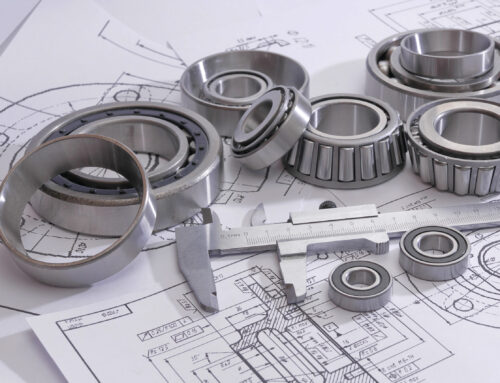

- Wear Resistance: Enhancing the surface properties of gears, shafts, and bearings to resist wear and tear.

- Corrosion Protection: Applying protective coatings to structures and components exposed to corrosive environments.

- Dimensional Restoration: Restoring worn or damaged parts to their original dimensions without the need for complete replacement.

- Electrical Conductivity: Creating conductive or insulative coatings based on specific industrial requirements.

Fusion Babbitting caters to industries seeking high-performance solutions, including power generation, maritime, manufacturing, and more.

Choosing Fusion Babbitting for Your Arc Spraying Needs

Selecting the right partner for arc spraying services is crucial for achieving the desired outcomes. Fusion Babbitting offers:

- Customized Solutions: Tailoring the arc spraying process to meet specific application requirements.

- Advanced Equipment: Utilizing state-of-the-art spraying technology for optimal coating quality and efficiency.

- Skilled Technicians: Our team’s expertise ensures precise application and superior finish.

- Comprehensive Support: From initial consultation to post-application assessment, we provide full-service support.

By partnering with Fusion Babbitting, you benefit from our dedication to quality, efficiency, and customer satisfaction.

Understanding the Arc Spraying Process with Fusion Babbitting

The arc spraying process is a cornerstone of modern industrial maintenance and manufacturing, offering a robust solution for enhancing component longevity and performance. Fusion Babbitting’s expertise in arc spraying provides industries with a reliable, efficient, and cost-effective service. Our commitment to excellence ensures that every project we undertake benefits from the highest standards of quality and innovation. Trust Fusion Babbitting to deliver the superior arc spraying solutions your operations require.