Sudden Equipment Failure: The Toll of Bearing Malfunctions

Imagine this: it’s a regular workday at your Milwaukee facility, and production is in full swing. Then suddenly, everything comes to a halt. The problem? A failed bearing. When industrial bearings go bad, the consequences can be catastrophic—unplanned downtime, lost revenue, and missed deadlines. If you’re facing this issue, what you need right now is an emergency bearing manufacturer Milwaukee can rely on. That’s where Fusion Babbitting comes in.

As industrial operations grow more complex, dependable equipment performance becomes more crucial. Bearings are the unsung heroes behind most heavy machinery in manufacturing plants, power stations, and pump systems. But when they fail, they often do so without warning. If you’re currently dealing with a bearing failure shutdown, help is available—and it’s closer than you think.

Why Bearings Are So Critical

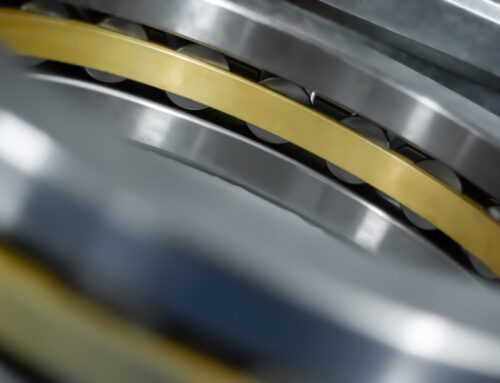

Bearings reduce friction and wear between moving parts, ensuring smooth operation and enhancing the life of industrial machines. Whether in turbines, pumps, or electric motors, bearings are designed to handle tremendous stress and heat. But even the best equipment can wear out or experience sudden failures due to:

– Extreme operating conditions

– Improper lubrication

– Misalignment

– Material fatigue

– Poor installation

Once a bearing fails, your plant operations could face long delays if replacements aren’t readily available. That’s why finding an emergency bearing manufacturer Milwaukee operators can trust is absolutely critical.

Introducing Fusion Babbitting: Milwaukee’s Emergency Bearing Manufacturer

Established in 1988 and based at 4540 W. Burnham St. in Milwaukee, Fusion Babbitting Co., Inc. stands out as the go-to expert in industrial bearing manufacturing and repair. With over 40 years of combined experience, Fusion Babbitting specializes in saving critical operations from costly downtime. They offer a reliable solution for any company in need of bearing failure shutdown help.

Fusion Babbitting isn’t just another machine shop. Their highly qualified team uses advanced techniques to repair, rebuild, or manufacture bearings to meet or exceed OEM (Original Equipment Manufacturer) standards. More importantly, they offer 24-hour emergency services designed for urgent needs. For businesses searching for an emergency bearing manufacturer Milwaukee trusts, Fusion Babbitting is the clear choice.

Services Designed to Get You Back up and Running—Fast

1. Bearing Repair, Rebabbitting, and Rebuilding

If your existing bearing is failing or worn out, Fusion Babbitting can quickly restore it to working condition. Using certified Babbitt metal and precision machining techniques, their rebuilt bearings match the original specifications—or even better. Their rebabbitting services are especially valuable for legacy or hard-to-find parts, extending equipment life and minimizing costs.

2. Precision Centrifugal Casting

Fusion Babbitting uses centrifugal casting to ensure strong metal bonding and consistent quality across each layer of their Babbitt material. This process reduces the risk of failure and extends bearing life, reducing long-term costs. By using centrifugal force to distribute molten Babbitt, the team ensures even thickness and optimal adhesion, which is vital for high-load environments.

3. Arc Flame Spray Application

For bearings and other components worn by high-friction environments, Fusion Babbitting uses arc flame spray technology to rebuild material surfaces. This adds a strong, wear-resistant coating that restores the component to its original dimensions. This technique also offers improved durability, reducing the frequency of future failures.

4. Reverse Engineering Obsolete Bearings

Got a machine with obsolete parts? No problem. Fusion Babbitting offers expert reverse engineering to recreate your bearing from scratch—even if all you have is a worn sample. They’ll produce detailed drawings and manufacture exact replicas tailored to your needs. This service is especially helpful for industries relying on older machinery that’s out of production.

5. Custom New Manufacturing

When off-the-shelf parts won’t work, you need custom solutions. Fusion Babbitting’s new manufacturing service uses precise engineering and high-quality materials to produce new bearings for a range of applications. Whether you’re in need of one bearing or dozens, they’ll meet your timeline—fast. Their state-of-the-art equipment allows them to quickly fabricate parts for a wide range of machines.

Industries That Rely on Fusion Babbitting

Fusion Babbitting supports a wide variety of industries. They understand that every second counts when you’re facing a bearing failure shutdown. Help from an experienced supplier with a deep knowledge of your sector can make all the difference. Industries served include:

– Aluminum Mills

– Cement and Chemical Plants

– Fossil and Nuclear Power Plants

– Hydro and Pump Storage Facilities

– Marine Repair and Shipyards

– Steel Mills and Mines

– Motor and Equipment Repair Shops

– Paper Mills

– Crushed Stone Producers

If your business, whether industrial or marine-based, relies on heavy-duty mechanical equipment, Fusion Babbitting can assist with emergency repairs and manufacturing. Their deep industry knowledge ensures they deliver fast and effective results across many sectors.

Equipment Types Serviced

Fusion Babbitting proudly supports an extensive range of industrial machinery. Whether you’re operating a hydroelectric power generator or a large-scale industrial pump, they have the skills and technology to rebuild or replace key bearing components. Equipment they commonly service includes:

– Electric Motors

– Pumps

– Hydro Power Systems

– Turbines

– Rotors and Shafts

From equipment as small as a pump bearing to large turbine housings, Fusion Babbitting can machine and fabricate parts up to 120 inches in length and diameter. That kind of flexibility is rare—and highly valuable in emergency situations. They also work with customers to evaluate current equipment performance and identify upgrades for better long-term outcomes.

Emergency Help When You Need It Most

Time is your most valuable asset during a mechanical breakdown. Fusion Babbitting understands that, and that’s why they offer 24-hour emergency services to minimize disruption. Their skilled experts are on call to assess damage, provide quick repair plans, and deliver custom-manufactured bearings on extremely short notice.

Whether it’s a holiday, weekend, or late night, if you’re searching for the emergency bearing manufacturer Milwaukee companies depend on, Fusion Babbitting is your best local option. Their reputation is built on precision, speed, and reliability. Their dedicated team responds quickly, communicates clearly, and produces the parts you need to minimize costly downtime.

Why Do Clients Choose Fusion Babbitting?

There are several things that separate Fusion Babbitting from other bearing manufacturers:

– Local Expertise: Based in Milwaukee, they understand the needs of Midwest industries

– Rapid Turnaround: Their repair and manufacturing shop runs 24/7 to support urgent orders

– Certified Materials: Only high-grade Babbitt alloys are used for strong, reliable repairs

– Advanced Technology: CNC machinery, arc flame spray coating, and centrifugal casting all ensure excellence

– Skilled Technicians: Over 40 years of combined team experience

– Nationwide Reach: Though located in Wisconsin, they provide nationwide support

Customers in dire need of bearing failure shutdown help often express gratitude for Fusion Babbitting’s speed and reliability. When every hour counts, this is the team you want on your side. Their results-driven approach ensures that quality is never sacrificed for speed.

Fusion Babbitting’s Commitment to Quality

Fusion Babbitting’s dedication to top-tier manufacturing starts with quality control. Every step of their bearing repair or manufacturing process involves careful inspection and adherence to tolerances. They understand that even minor measurement errors can result in major performance issues, which is why each component is thoroughly tested before delivery. Their ISO-compliant practices further ensure their bearings meet stringent industry standards.

From the use of certified Babbitt metals to comprehensive dimensional checks, their team goes above and beyond to deliver reliable, long-lasting components. Customers frequently report improved machine performance and longer operational life after using Fusion Babbitting’s services. That’s why they’ve become the preferred emergency bearing manufacturer Milwaukee and nationwide businesses count on.

Contact Fusion Babbitting Today

If your plant is down and you suspect a bearing failure is involved, don’t wait. Every moment of downtime costs your business money. Call the emergency bearing manufacturer Milwaukee knows for quick action and long-term solutions—Fusion Babbitting Co., Inc.

– Address: 4540 W. Burnham St., Milwaukee, WI 53219

– Phone: 414.645.5800 | Toll-Free: 800.613.5118

– Email: sales@fusionbabbitting.com

Whether you need an urgent repair, a freshly manufactured bearing, or a rebuilt obsolete part, Fusion Babbitting is ready. Your operation can’t wait. You need bearing failure shutdown help now—and they deliver. Their team is equipped to handle even the most urgent jobs with professionalism, speed, and accuracy.

Conclusion: Stop the Shutdown, Start the Fix

If you’re facing the costly reality of a plant shutdown due to bearing failure, make the smart move and contact Fusion Babbitting. As the top choice for an emergency bearing manufacturer Milwaukee facilities trust, they specialize in quick turnarounds and quality craftsmanship. With expert services like repair, rebabbitting, casting, and reverse engineering, Fusion Babbitting helps industrial operations recover fast and stay strong for the future.

Don’t let a bearing mishap bring your productivity to a standstill. The solution is just a phone call or email away. Reach out to Fusion Babbitting and get your plant back in motion—fast, efficiently, and with confidence.