Understanding the Babbitting Process: From Start to Finish

When it comes to industrial machinery, the quality of your Babbitt bearings can make all the difference. Understanding the Babbitting process is crucial to appreciate the intricacies and craftsmanship that goes into each bearing. In this post, we’ll walk you through the Babbitting process from start to finish.

What Is Babbitting?

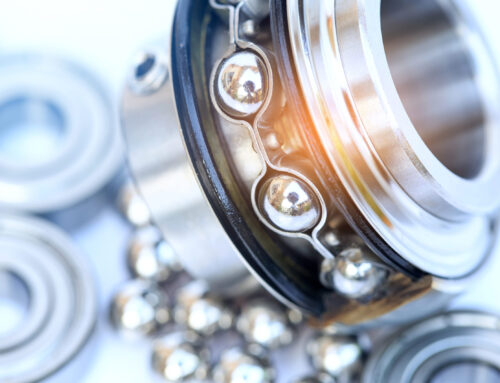

Babbitting is the process of lining a bearing surface with Babbitt metal, a soft, white, anti-friction metal alloy. Babbitt bearings provide a smooth, low friction surface for the rotating shaft in machinery.

The Babbitting Process: Step-by-Step Guide

Step 1: Preparing the Bearing Shell

The first step in the Babbitting process is to clean and prepare the bearing shell. This involves removing any old Babbitt metal and thoroughly cleaning the shell.

Step 2: Applying the Babbitt Metal

Next, molten Babbitt metal is poured into the bearing shell, forming a smooth lining. This step requires precision and expertise to ensure a perfect fit.

Step 3: Machining the Bearing

After the Babbitt metal has cooled and hardened, the bearing is machined to the exact specifications required for the machinery it will be used in.

Step 4: Quality Assurance

The final step in the Babbitting process is a comprehensive quality check. This includes inspecting the bearing for any defects and testing it to ensure optimal performance.

Why Choose Fusion Babbitting for Your Babbitting Needs

At Fusion Babbitting, we take pride in our meticulous Babbitting process, ensuring high-quality bearings that stand the test of time. With services in all 50 states, we’re committed to delivering top-notch Babbitt bearings for all your industrial machinery needs.

Understanding the Babbitting process helps to appreciate the craftsmanship that goes into creating Babbitt bearings. At Fusion Babbitting, our expertise and dedication to quality set us apart. Contact us today to learn more about our Babbitting services!