Why Do Motors Keep Failing After Repairs

When an electric motor fails, gets repaired, and then fails again months later, the usual blame falls on operating conditions. Sometimes that is true. Heat, contamination, imbalance, and misalignment all take a toll. But when the pattern repeats, it is time to look deeper. In many cases, the hidden cause is improper rebabbitting of the bearing. The bearing is a small part of the motor, yet it is fundamental to load support and oil film formation. If the rebabbitting process is not done correctly, the motor will keep burning time and money on repeated failures. In this blog, you will learn what rebabbitting is, how it goes wrong, how to catch the signs early, and how to prevent the next failure with proven best practices. Fusion Babbitting has been helping shops and plants stop chronic failures since 1988, and our team is ready to help you solve the root cause.

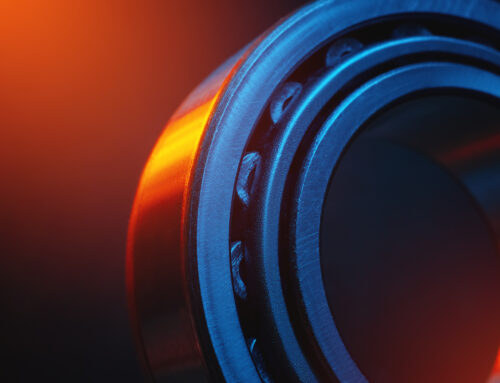

What Is Rebabbitting and Why It Matters

Rebabbitting is the process of renewing the soft Babbitt lining inside a bearing shell. Over time, the Babbitt wears or fatigues. In a proper rebabbitting job, technicians remove the old lining, prepare the shell, cast or apply new Babbitt, bond test it, machine it to the correct geometry, cut oil grooves, and verify clearances and alignment. Done right, the bearing supports a stable oil film, runs cool, and protects the shaft and housing. Done wrong, it introduces hidden defects that show up as heat, vibration, wipe, wipe-repair cycles, and premature failure. This is why the quality of rebabbitting is tied directly to motor reliability and uptime.

How Improper Rebabbitting Triggers Repeat Failures

Poor Babbitt Bond and Inadequate Shell Prep

A strong bond between the steel or bronze shell and the Babbitt is non-negotiable. If the shell is not fully cleaned, tinned, and prepped with the right anchor pattern, the Babbitt can delaminate under load and heat. Bond separation starts small and grows into wipe, debris, and then a full failure. Fusion Babbitting uses controlled preparation steps and bond testing to ensure lasting adhesion.

Wrong Casting Method or Parameters

Static pours can trap gas and yield inconsistent microstructure. For many bearing designs, centrifugal casting creates a dense, uniform lining with excellent bond integrity. The wrong temperature, pour rate, or material selection can weaken the lining. Fusion Babbitting relies on certified Babbitt alloys and centrifugal casting procedures to produce consistent results.

Incorrect Oil Clearance and Geometry

Oil film reliability depends on accurate clearances and geometry. If the bearing is machined with too little clearance, it runs hot and wipes. Too much clearance causes instability and vibration. Incorrect bore geometry, crooked split lines, or poor roundness will starve parts of the loaded zone of oil. Proper machining and inspection are key to stable operation.

Groove and Relief Errors

Oil grooves and reliefs are not cosmetic. Their shape and location control oil delivery, pressure balance, and return flow. Sloppy groove design or sharp edges can promote film collapse and local wipe. Precision groove cutting in the final machining step helps protect the film and reduce heat.

Contamination and Inclusion Defects

Dust, chips, and oil sludge trapped in the lining during casting or machining can seed cracks and spalls. Cleanliness is vital at every step. A controlled environment and disciplined handling reduce this risk. Fusion Babbitting enforces strict cleanliness and inspection at each stage.

Metallurgy Mismatch

Not all Babbitt alloys are equal. The wrong alloy for the load, speed, or temperature range can fail prematurely. Traceability to certified materials is essential. Fusion Babbitting uses certified Babbitt materials matched to your application.

Insufficient Quality Control

Lack of bond checks, hardness tests, dimensional reports, and runout checks can let hidden defects slip through. Robust documentation and final inspections help prevent future failures. Our team provides clear inspection records and measurements to align with or exceed OEM specs.

Field Symptoms That Point to Rebabbitting Issues

Many field symptoms are linked to process errors in rebabbitting. If you see these warning signs, investigate the bearing first.

- Rising bearing temperature shortly after commissioning

- Frequent alarms during ramp-up or after load changes

- Localized wipe marks or scoring on the Babbitt lining

- Unusual oil discoloration, metallic sheen, or debris

- Growing axial or radial vibration with no alignment change

- Frequent oil leaks or foaming due to poor groove relief

- Repeated need to polish or scrape without lasting improvement

- Early thrust pad distress in units sharing the same oil system

How to Confirm Rebabbitting as the Root Cause

Use a focused approach to isolate the bearing as the cause of repeat failures. The steps below reduce guesswork and help you make the right repair decisions.

- Interview and history: Capture operating conditions, previous repair vendors, failure timelines, and oil analysis trends.

- Dimensional checks: Measure bore size, roundness, split line geometry, and oil clearances at multiple clock positions.

- Bond assessment: Perform dye penetrant on cracks, inspect for lift at the shell interface, and review bond test records.

- Surface and groove review: Look for sharp groove edges, mislocated feed holes, or burrs that could disrupt oil flow.

- Metallurgical review: Verify alloy type, hardness, and microstructure against the intended application.

- Shaft and housing checks: Confirm shaft journal finish, taper, runout, and alignment, as well as housing fit and cleanliness.

- Oil system audit: Validate oil grade, temperature, flow, and filtration to guard against external aggravators.

- Documentation verification: Ensure the repair included material certs, bond test results, and dimensional inspection reports.

Best Practices for Reliable Rebabbitting

Start With the Right Materials

Select a certified Babbitt alloy matched to speed, load, and temperature. Keep material traceability records. Confirm compatibility with your lubricant and expected operating range.

Use Controlled Casting Methods

Centrifugal casting provides uniform bond and structure for many bearing sizes. Control preheat, pour temperature, and rotational speed to avoid porosity and segregation. Fusion Babbitting specializes in centrifugal casting to deliver strong, consistent bonds.

Prepare the Shell Thoroughly

Remove old lining completely. Clean, tin, and texture the shell to the correct anchor pattern. Verify cleanliness before casting. Proper surface prep is the foundation of a durable bond.

Machine to Tight Tolerances

After casting, machine the bore to exact geometry. Validate roundness, taper, and diameter. Cut oil grooves to approved patterns. Deburr all edges. Check fit at the split line. Confirm clearances against OEM or engineered specs.

Inspect the Bond and Microstructure

Perform bond tests and visual inspections for inclusions. Review alloy hardness and structure. Keep test results with the job traveler for quality tracking.

Balance Grease and Oil Considerations

Match the bearing design to the lubricant and supply method. Oil-lubricated bearings need feed holes, reliefs, and drains placed for proper film stability. Grease-lubricated bearings need controlled clearances and sealing practices.

Document Everything

Provide certificates for materials, final dimensions, bond tests, and fit recommendations. Clear documentation makes future troubleshooting faster and protects uptime.

Install With Care

Before installation, clean mating surfaces, verify housing fit, and check alignment. Use correct torque and doweling. Confirm oil flow and temperature controls on startup. A good bearing can still fail when installed in a misaligned or contaminated housing.

Plan for Break-In and Monitoring

Use a controlled warm-up. Monitor temperature, vibration, and oil cleanliness during break-in. Take baseline readings for future comparison. If readings trend upward, stop and inspect rather than running to failure.

When to Consider Advanced Repairs Beyond Rebabbitting

Some chronic problems stem from wear on the housing or shaft. In these cases, advanced restoration may be needed. Fusion Babbitting offers arc flame spray application to restore worn components and then machines them back to specification. For obsolete or hard-to-find bearings, our reverse engineering service reproduces the part with precise drawings and fits that match or exceed the original design. When a bearing or component is beyond repair, our new manufacturing capability delivers custom, high-precision products that drop into your equipment and run reliably.

Why Work With Fusion Babbitting

Fusion Babbitting Co., Inc. has focused on bearing reliability since 1988. Based in Milwaukee, Wisconsin at 4540 W. Burnham St., we serve customers nationwide with 24-hour emergency response. Our team combines over 40 years of experience with advanced equipment for repair, rebabbitting, rebuilding, reverse engineering, and custom manufacturing. We handle components up to 120 inches in diameter and length, which covers a wide range of large industrial machinery. Our services include centrifugal casting of certified Babbitt materials, arc flame spray restoration, general fabrication and machining, and precise new manufacturing.

Fusion Babbitting works across industries where uptime is essential, including aluminum mills, cement and chemical plants, fossil and nuclear plants, hydro and pump storage, marine repair, mines and steel mills, motor repair shops, paper mills, shipyards, and crushed stone producers. If you depend on electric motors, hydro power systems, pumps, or turbines, our team understands the demands of your application and the standards that keep your equipment running. We meet or exceed OEM specifications and back our work with clear documentation and support.

Real-World Example of Rebabbitting Done Right

A motor repair shop kept seeing a 2000 horsepower motor fail within months of overhaul. The bearing ran hot and showed wipe on the loaded zone. Alignment checks looked good, oil quality was in range, and the load did not change. The shop sent the bearings to Fusion Babbitting for evaluation. Our inspection showed poor bond in the previous lining, with contamination pockets and inconsistent oil groove depth. The oil clearance was tight near the split line and oversize opposite the load.

We stripped the lining, prepared the shell, and performed centrifugal casting using a certified alloy matched to the speed and load. We bond tested the lining, machined the bore to correct geometry, and cut new groove patterns with smooth transitions. Final inspection included roundness, clearance mapping, and documentation for the shop. After installation, the motor ran cooler and vibration levels dropped. The unit passed its break-in period and remained in service beyond the previous failure window. The lesson was clear. Correct rebabbitting stopped the failure cycle.

Action Checklist to Prevent the Next Failure

- Confirm your rebabbitting vendor uses certified Babbitt alloys and can provide traceability.

- Request bond test results, hardness checks, and full dimensional inspection reports.

- Verify centrifugal casting when appropriate for your bearing size and type.

- Check that oil grooves and reliefs match your lubrication method and OEM guidance.

- Measure clearance and roundness at multiple clock positions after installation.

- Audit alignment, shaft finish, and housing fit before startup.

- Set a controlled break-in plan with temperature and vibration monitoring.

- Keep oil clean and within the right temperature and viscosity range.

- Retain documentation for future reference and trend analysis.

- Schedule a reliability consult with Fusion Babbitting if failures repeat.

Common Questions About Rebabbitting

How often should a bearing be rebabbitted

There is no set interval. It depends on load, speed, temperature, oil quality, and alignment. Monitor temperature and vibration, inspect oil and filters, and check clearances during planned overhauls. Rebabitting should occur when wear, wipe, or damage is found, or when inspection shows bond issues.

Is centrifugal casting always better

Centrifugal casting offers strong bond integrity and uniform structure for many bearings, especially larger sizes. Some small or special designs may use other methods. The right process depends on the bearing design and application. Fusion Babbitting evaluates each job and selects the method that best fits reliability goals.

Can rebabbitting fix misalignment problems

No. Rebabbitting restores the lining, not the alignment. If misalignment or shaft defects exist, the bearing will still fail. Always verify alignment, shaft condition, and housing fit during installation.

What documentation should I expect after rebabbitting

You should receive material certifications, bond test results, hardness or microstructure checks when requested, final dimensions and roundness, oil groove layout, and recommended clearances. This documentation proves the work and speeds troubleshooting if issues arise.

Book a Reliability Consult With Fusion Babbitting

If repeated motor failures are hitting your budget and schedule, rebabbitting quality should be at the top of your review. Fusion Babbitting brings proven processes, certified materials, and tight machining controls to every bearing. We can reverse engineer obsolete parts, restore worn components with arc flame spray, and manufacture new precision bearings when needed. Our team serves clients nationwide with 24-hour emergency service from Milwaukee.

Contact Fusion Babbitting today to discuss your application, request a quote, or schedule a reliability consult. Address: 4540 W. Burnham St., Milwaukee, WI 53219. Phone: 414.645.5800. Toll-free: 800.613.5118. Email: sales@fusionbabbitting.com. We are ready to help you stop repeat failures at the source and keep your equipment running reliably.

About Fusion Babbitting

Fusion Babbitting Co., Inc. specializes in Babbitt bearing services for demanding industries. Our core offerings include repair, rebabbitting, and rebuilding to meet or exceed OEM specs. We deliver strong bond strength through controlled centrifugal casting and use certified materials to ensure long-term performance. Our arc flame spray capability restores worn components that would otherwise need replacement. When legacy parts are no longer available, our reverse engineering team creates precise replicas with detailed drawings. We also offer general fabrication and machining for components up to 120 inches in diameter and length, plus custom new manufacturing for OEMs and end users.

Whether you operate aluminum mills, cement and chemical plants, fossil or nuclear facilities, hydro and pump storage, marine vessels, mines and steel mills, motor repair shops, paper mills, shipyards, or crushed stone operations, Fusion Babbitting understands your environment and your deadlines. Our focus is reliability, documentation, and uptime. If rebabbitting is part of your maintenance plan, we are your partner for consistent quality and measurable results.

Repeated motor failures often trace back to improper rebabbitting. By choosing a proven rebabbitting partner and following best practices, you can eliminate hidden bearing defects, stabilize the oil film, and protect your equipment investment. Fusion Babbitting is ready to help you do exactly that.