Understanding Pump Bearings: A Comprehensive Guide for 2024

In the world of machinery, bearings are vital components that ensure smooth and efficient operation. Pump bearings, in particular, are crucial for the optimal performance of various types of pumps. This blog will delve into the details of pump bearings, exploring their types, applications, and how to choose the right one for your machinery needs in 2024.

What Are Pump Bearings?

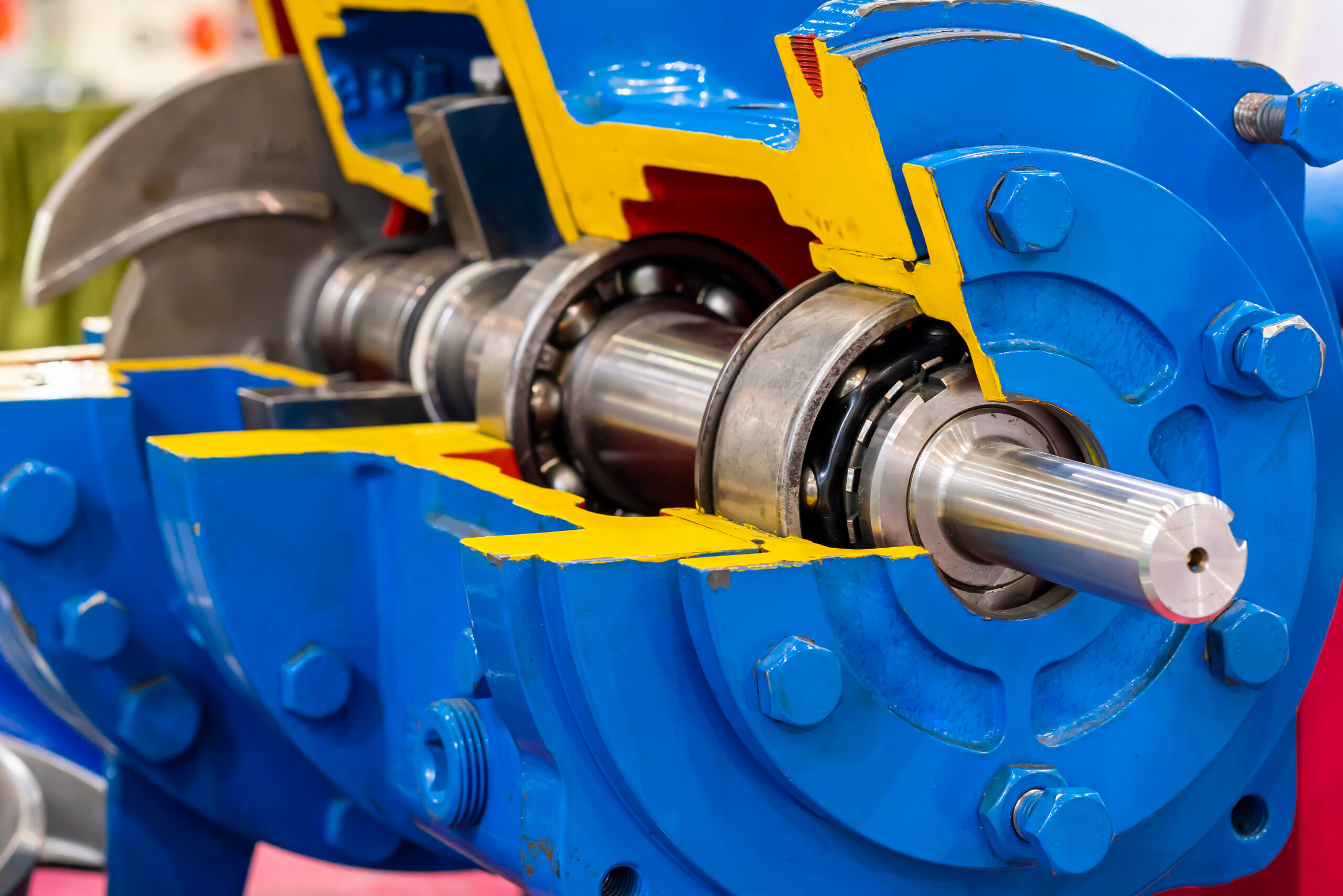

Pump bearings are specialized bearings designed to support the shafts of pumps, reducing friction and wear. They are essential for maintaining the alignment and stability of pump components, ensuring efficient and reliable operation.

Types of Pump Bearings

- Sleeve Bearings: These are simple, cylindrical bearings that provide a smooth surface for the pump shaft to rotate within.

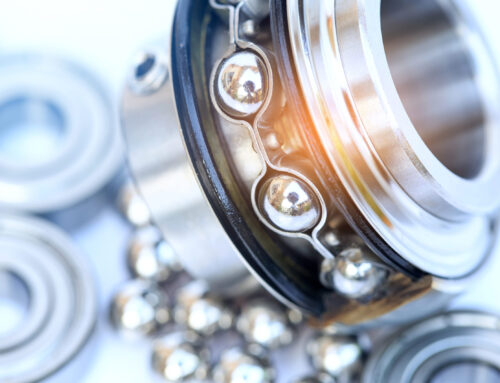

- Ball Bearings: Consist of rolling balls placed between two rings, allowing smooth rotation with minimal friction.

- Roller Bearings: Use cylindrical rollers instead of balls, providing greater load capacity and durability.

Key Features of Pump Bearings

- Load Capacity: Pump bearings are designed to handle the specific loads generated by pump operation.

- Durability: Made from high-quality materials to withstand harsh operating conditions.

- Low Maintenance: Engineered to require minimal maintenance while providing long service life.

Applications of Pump Bearings

Pump bearings are used in a variety of industries and applications, each with its unique requirements.

Industrial Pumps

In industrial settings, pump bearings are essential for the reliable operation of pumps used in manufacturing, chemical processing, and other heavy-duty applications. These bearings must handle high loads and continuous operation.

Automotive Pumps

In the automotive industry, pump bearings are used in water pumps, fuel pumps, and oil pumps. These bearings must provide smooth, reliable operation under varying conditions, including high temperatures and pressures.

Household Pumps

Pump bearings are also found in household appliances such as washing machines, dishwashers, and HVAC systems. These applications require bearings that are quiet, efficient, and durable.

Choosing the Right Pump Bearings

Selecting the right pump bearings for your application involves considering several factors to ensure optimal performance and longevity.

Load and Speed Requirements

- Load Capacity: Choose bearings that can handle the specific loads generated by your pump.

- Speed: Ensure the bearings are rated for the operating speed of your pump.

Environmental Conditions

- Temperature: Select bearings that can withstand the operating temperatures of your pump.

- Contaminants: Consider bearings with seals or shields to protect against dirt, dust, and moisture.

Maintenance and Longevity

- Maintenance Requirements: Choose bearings that require minimal maintenance and are easy to replace if needed.

- Durability: Opt for high-quality bearings made from materials that can withstand wear and tear.

Advantages of Using High-Quality Pump Bearings

Investing in high-quality pump bearings can offer several benefits, ensuring the efficient and reliable operation of your pumps.

Improved Efficiency

High-quality pump bearings reduce friction and wear, resulting in smoother operation and improved efficiency. This can lead to energy savings and lower operating costs.

Extended Service Life

Durable pump bearings can extend the service life of your pumps, reducing the frequency of repairs and replacements. This can result in significant cost savings over time.

Reduced Maintenance

Pump bearings designed for low maintenance can minimize downtime and reduce the need for frequent servicing. This can enhance the overall productivity of your operations.

Fusion Babbitting: Your Source for Premium Pump Bearings

At Fusion Babbitting, we specialize in providing top-quality pump bearings that meet the unique needs of various industries. Our expertise and commitment to quality ensure that you receive the best bearing solutions for your applications.

Our Bearing Solutions

- Custom Manufacturing: We offer custom manufacturing services to provide bearings tailored to your specific requirements.

- Rebuilds and Repairs: Our rebuild and repair services can restore your bearings to optimal condition, extending their service life.

- Rebabbitting: We provide rebabbitting services to refurbish worn bearings, ensuring they perform like new.

Why Choose Fusion Babbitting?

- Expertise: With years of experience, we have the knowledge and skills to deliver the best bearing solutions.

- Quality: We use only high-quality materials and advanced techniques to ensure the durability and reliability of our bearings.

- Customer Satisfaction: We are committed to providing exceptional service and support to our customers, ensuring your complete satisfaction.

Conclusion: Optimizing Your Pump Performance with the Right Bearings

Choosing the right pump bearings is crucial for the efficient and reliable operation of your pumps. By understanding the types of bearings available and considering factors such as load capacity, speed, and environmental conditions, you can select the best bearings for your needs. At Fusion Babbitting, we are here to provide expert guidance and high-quality bearing solutions to help you achieve optimal pump performance. Contact us today to learn more about our services and how we can assist you with your bearing needs.