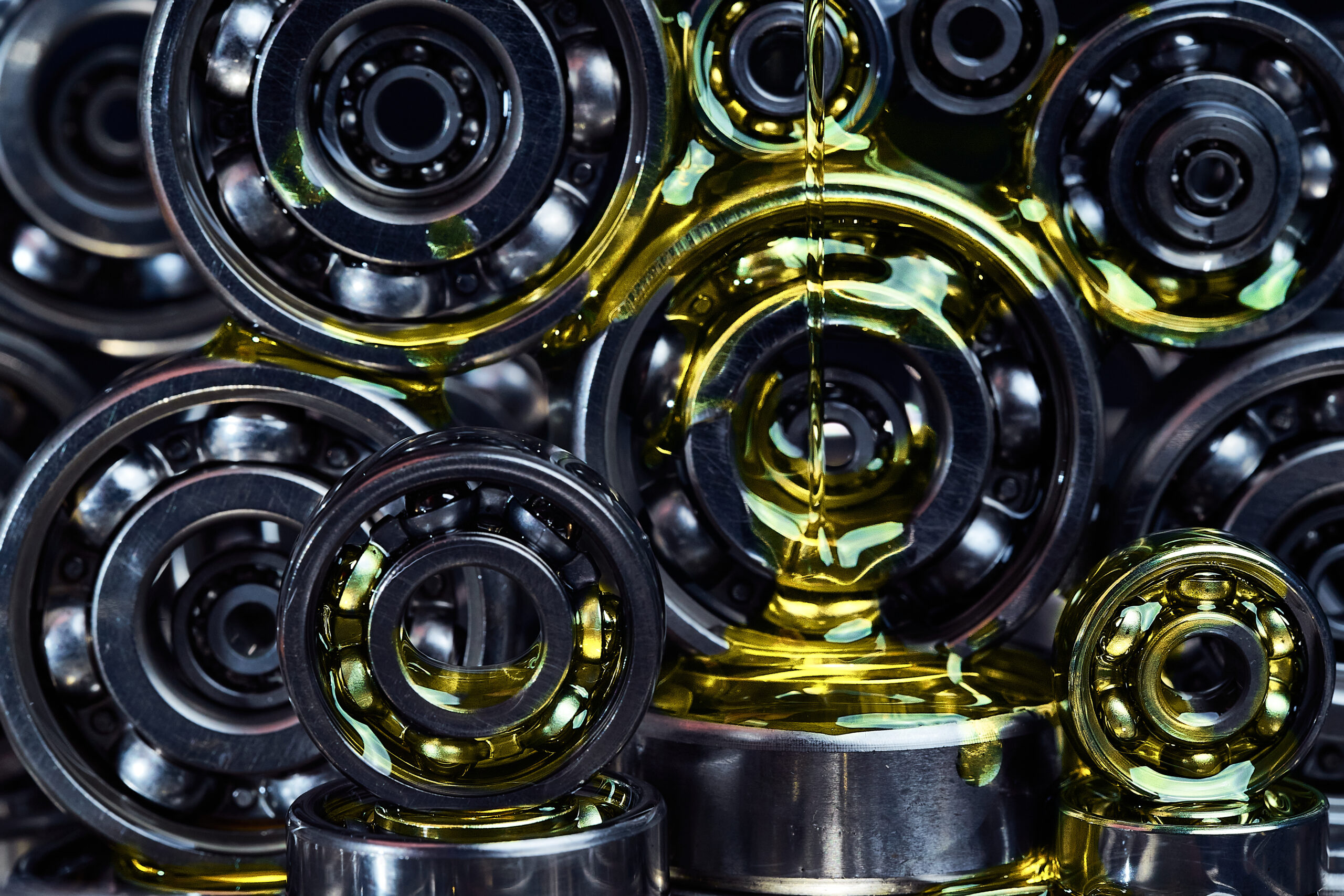

What Are Oil-Lubricated Bearings?

Oil-lubricated bearings are a type of bearing system that uses oil as the lubricating fluid to reduce friction between moving parts. These bearings are essential for the smooth and efficient functioning of many machines found in industrial, marine, and energy sectors. Unlike grease-lubricated bearings, oil-lubricated bearings provide better cooling, support higher speeds, and manage heavy loads more effectively. For businesses looking to boost machinery performance and minimize downtime, oil-lubricated bearings are a highly reliable solution. Fusion Babbitting plays a vital role in this field by offering top-notch bearing repair and manufacturing services to support machinery that uses oil-lubricated systems.

The Advantages of Oil-Lubricated Bearings

Superior Lubrication and Performance

Oil-lubricated bearings offer enhanced lubrication properties compared to grease or dry-lubricated options. Oil can flow over moving parts more freely, reducing wear and increasing bearing life. This type of lubrication can also dissipate heat more effectively, which is crucial for high-speed rotating equipment like turbines and motors. Fusion Babbitting understands the importance of maintaining lubrication integrity and offers high-quality Babbitt materials for superior bearing life.

Heat Dissipation

In high-performance machinery, heat can become a significant issue. Oil helps transfer heat away from the bearing surfaces, preventing damage caused by overheating. This is especially critical in operations involving electric motors, pumps, and turbines, where temperature control is essential for efficiency and longevity. Fusion Babbitting helps extend the operational life of your equipment by ensuring that all refurbished bearings meet high heat dissipation requirements.

Contaminant Removal

Oil can be filtered and circulated through systems to remove dirt, debris, and metallic particles, maintaining cleaner surfaces within the bearing. Cleaner systems reduce the occurrence of breakdowns, which leads to fewer repairs and less unplanned downtime. Fusion Babbitting’s machining and fabrication services ensure that bearing components are free of contaminants and returned to like-new condition.

Longer Equipment Life

By reducing friction, removing heat, and keeping components clean, oil-lubricated bearings extend the life of mechanical systems. This benefit is especially attractive to industries such as steel mills, power plants, and shipyards that rely on heavy-duty and continuous operations. Proper maintenance from certified repair partners like Fusion Babbitting helps maximize this advantage and reduce lifecycle costs.

Cost-Effective Over Time

While oil systems may require more initial investment than simpler solutions like grease, they offer better long-term operational savings. Reduced maintenance, fewer part replacements, and less downtime all contribute to a lower total cost of ownership. With Fusion Babbitting’s trusted repair and reverse engineering capabilities, clients often save money by refurbishing rather than replacing expensive bearing components.

Key Applications of Oil-Lubricated Bearings

Electric Motors

Electric motors often run for long hours at variable speeds. Oil-lubricated bearings help ensure consistent performance and reduce the need for frequent shutdowns and maintenance. Fusion Babbitting specializes in rebabbitting and rebuilding electric motor bearings to meet or exceed original equipment manufacturer (OEM) standards, helping manufacturers avoid unnecessary replacements.

Pumps

Industrial pumps used in water treatment, chemical plants, and mining rely heavily on oil lubrication to maintain smooth operation. Oil circulation helps manage heat and pressure—ensuring reliability in mission-critical applications. Fusion Babbitting provides refurbishing services that restore pump bearings to optimal condition, using high-quality Babbitt materials for extended durability and smoother performance.

Turbines

Steam, gas, and hydro turbines operate under extreme loads and temperatures. Oil-lubricated bearings are crucial in managing these conditions. Fusion Babbitting serves clients in fossil and nuclear power plants by offering expert turbine bearing repairs and replacements through centrifugal casting and precision machining. Their work ensures that the high demands of turbine machinery are met consistently.

Hydroelectric Systems

Hydropower systems often run non-stop and feature large rotating components. Oil helps manage their load and enhances the life of bearings situated in wet, high-pressure environments. Fusion Babbitting’s reverse engineering services can recreate obsolete bearings, extending the life of legacy hydroelectric equipment and avoiding the high cost of complete system replacements.

Marine and Shipyard Equipment

Marine vessels and shipyard cranes must operate under coastal and salty conditions. Oil-lubricated bearings reduce rust, resist contamination, and perform reliably in marine environments. Fusion Babbitting works with marine repair facilities, offering 24-hour emergency services to minimize port time and disruptions, ensuring that key operations stay on course and on schedule.

Industries That Rely on Oil-Lubricated Bearings

Oil-lubricated bearings play a key role in several major industries. Fusion Babbitting proudly partners with companies across diverse sectors to keep their operations running every day.

– Aluminum Mills: High-speed rolling operations produce substantial heat that can damage lesser bearing systems. Oil-lubricated bearings manage this heat effectively.

– Cement and Chemical Plants: These facilities demand non-stop equipment reliability, particularly in high-pressure settings where oil bearings maintain performance.

– Fossil and Nuclear Power: Turbine performance is critical, and oil-lubricated bearings prevent unplanned outages by managing heat and load stress.

– Hydro/Pump Storage: Efficient energy storage and water flow management depend on robust oil-bearing systems found in massive infrastructure projects.

– Marine Repair and Shipyards: Dock operations and naval equipment rely on durable, corrosion-resistant oil-lubricated bearings to withstand harsh marine environments.

– Mining and Steel Mills: These heavy industries put immense pressures on machinery. Lubricated bearings reduce wear and boost performance for crushing, conveying, and refining equipment.

– Motor Repair Shops: Maintaining and servicing motors with proper oil lubrication ensures equipment longevity and minimizes return visits.

– Paper Mills: Constant operations and narrow tolerances require precision lubrication that oil-lubricated bearings provide reliably, enabling sustained output.

– Crushed Stone Producers: Bearings keep crushers and conveyors working under extreme dust and load conditions. Oil prevents system failure caused by heat and debris.

Choosing the Right Partner for Bearing Services

When it comes to maintaining or upgrading oil-lubricated bearings, choosing the right partner can make all the difference. Fusion Babbitting Co., Inc., based in Milwaukee, WI, brings over 40 years of bearing expertise to clients across the country. Since 1988, they’ve focused on rebuilding and manufacturing high-performance bearings that match or exceed OEM specifications. Their dedication to quality has made them a trusted name in the repair and manufacturing of oil-lubricated bearings.

Fusion Babbitting’s Full Range of Services

Fusion Babbitting offers a variety of specialized services to support oil-lubricated bearing maintenance:

– Repair, Rebabbitting, and Rebuilding: Their skilled team refurbishes bearings with Babbitt metal to return them to like-new condition, extending the lifespan of equipment.

– Centrifugal Casting: This process creates a strong bond between the bearing surface and housing, improving durability and preventing separation during demanding operations.

– Arc Flame Spray: Used to restore worn components and resurface areas back to operational specs, ensuring tight mechanical tolerances.

– Reverse Engineering: When parts are no longer available, Fusion Babbitting can recreate them from samples or blueprints, eliminating downtime due to discontinued components.

– General Fabrication and Machining: They handle large-scale jobs up to 120 inches in diameter or length with precision, supporting industrial-scale applications.

– Custom Manufacturing: OEMs can turn to Fusion Babbitting for new, high-precision parts tailored to their project’s unique requirements, improving equipment design and reliability.

Emergency Service and Nationwide Support

Downtime can be costly. That’s why Fusion Babbitting offers 24-hour emergency support to get your equipment back online quickly. Located at 4540 W. Burnham St., Milwaukee, they can ship or receive parts nationwide and deliver fast turnaround times that keep operations moving. Their quick response, logistics network, and years of experience make them the go-to service provider for critical equipment needs.

Best Practices for Oil-Lubricated Bearing Maintenance

Regular Inspection

Routine inspections can catch early signs of wear, oil leakage, and contamination. Bearings should be examined for surface damage, vibration issues, and temperature fluctuations. Catching problems early can prevent expensive system failures. Fusion Babbitting can assist in scheduled inspections and guide clients through best practices for bearing assessment.

Oil Analysis

Periodic testing of the oil inside the bearing can reveal much about system health. Look for changes in viscosity, unusual particles, or chemical degradation, which signal the need for oil replacement or further inspection. Fusion Babbitting works with clients to assess oil condition and advise on condition-based maintenance strategies.

Proper Cleaning and Seals

Contaminants like water, dust, or chemicals can enter bearing housings and lead to failure. Make sure seals are intact and conduct regular cleaning to protect all internal parts. Fusion Babbitting can assist in choosing the right seals or refurbishing the housing to avoid oil leaks and keep lubrication systems enclosed and uncontaminated.

Scheduled Oil Changes

Oil changes are vital to optimal bearing performance, just like with automotive engines. Following manufacturer guidelines or working with bearing specialists like Fusion Babbitting can help determine appropriate intervals, especially in demanding environments. Reliable oil service extends bearing life and ensures ongoing operational efficiency across sectors

Why Choose Fusion Babbitting?

With a strong reputation in Babbitt bearing repair and a long history of meeting industrial needs, Fusion Babbitting is a trusted choice for keeping critical machines in top shape. Their commitment to quality, attention to detail, and investment in advanced equipment ensure clients receive long-lasting solutions. Fusion Babbitting applies best practices to each project, ensuring maximum performance and compliance with OEM specifications.

From reverse engineering obsolete bearings to manufacturing custom parts for OEMs, their team stands ready to help industries stay productive and profitable. Whether you’re dealing with turbines, pumps, or electric motors, Fusion Babbitting’s oil-lubricated bearing expertise can lengthen equipment life and improve efficiency. For more information, contact them at 414.645.5800 or toll-free at 800.613.5118, or email sales@fusionbabbitting.com.

Conclusion

Oil-lubricated bearings are essential for ensuring the smooth, efficient, and long-lasting performance of heavy-duty industrial equipment. They excel in managing high speeds, intense loads, and extreme temperatures, making them a preferred choice across multiple sectors. Effective maintenance, proper component selection, and expert service are key to getting the most from oil-lubricated systems. Fusion Babbitting offers industry-leading services in Babbitt bearing repair, manufacturing, and maintenance. Their extensive experience, advanced technologies, and nationwide reach make them the ideal partner for companies that rely on high-performance bearings. Don’t leave equipment reliability to chance—let Fusion Babbitting help your operation run smoother with expertly serviced oil-lubricated bearings.