Journal vs Ball Bearing: Which Is Right for Your Machinery?

When it comes to machinery and equipment, bearings play a crucial role in ensuring smooth and efficient operation. Two common types of bearings used in various applications are journal bearings and ball bearings. Understanding the differences between these two types can help you make an informed decision for your machinery needs. In this blog, we’ll explore the key differences between journal and ball bearings, their applications, and which might be the best fit for your needs in 2024.

What Are Journal Bearings?

Journal bearings, also known as plain bearings, are simple bearings that consist of a shaft or journal rotating within a supporting sleeve or shell. These bearings rely on a thin film of lubricant to reduce friction between the moving parts.

Advantages of Journal Bearings

- High Load Capacity: Journal bearings can handle heavy loads, making them ideal for applications such as turbines and compressors.

- Durability: They are known for their long lifespan, especially when properly maintained.

- Low Maintenance: With fewer moving parts, journal bearings require less maintenance compared to ball bearings.

Common Applications for Journal Bearings

Journal bearings are commonly used in heavy machinery and equipment where high load capacity is essential. Some typical applications include:

- Turbines

- Compressors

- Electric motors

Real-World Examples

In power plants, journal bearings are used in large turbines to ensure smooth rotation and efficient energy generation. These bearings can support the massive weights and stresses involved, providing reliable performance over long periods.

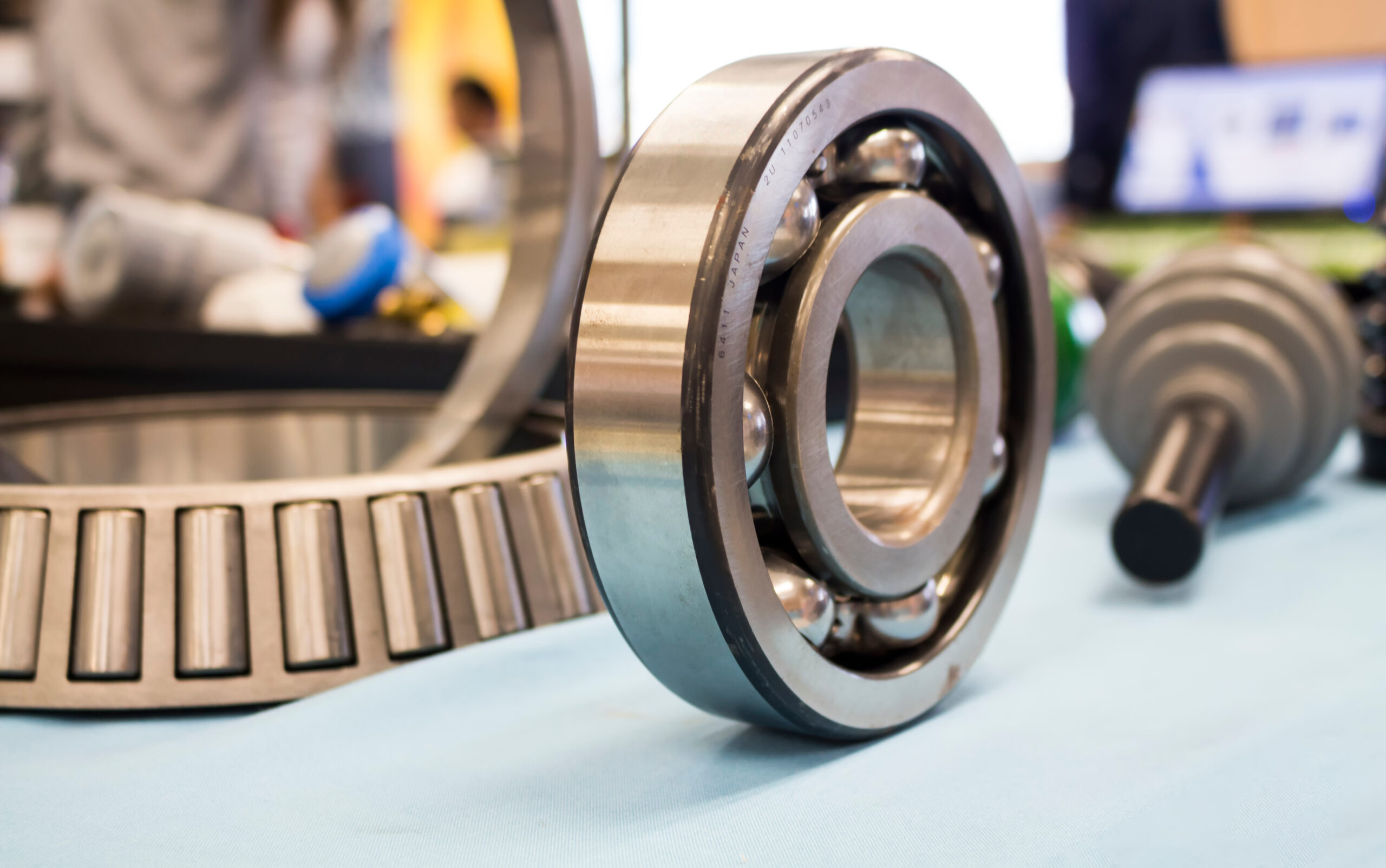

What Are Ball Bearings?

Ball bearings consist of rolling balls placed between two rings, known as races. The balls reduce friction by allowing smooth movement between the races, enabling rotation with minimal resistance.

Advantages of Ball Bearings

- Low Friction: Ball bearings provide low friction, which results in smooth operation and reduced wear and tear.

- High Speed: These bearings are suitable for high-speed applications, making them ideal for precision equipment.

- Versatility: Ball bearings are versatile and can be used in a wide range of applications.

Common Applications for Ball Bearings

Ball bearings are found in various applications where high speed and low friction are crucial. Some typical uses include:

- Automotive industry

- Aerospace industry

- Industrial machinery

Real-World Examples

In the automotive industry, ball bearings are used in wheel hubs to ensure smooth and efficient rotation. This application requires high-speed performance and low friction, making ball bearings the ideal choice.

Journal vs Ball Bearing: Key Differences

When deciding between journal and ball bearings, it’s essential to understand the key differences that set them apart.

Load Capacity

- Journal Bearings: Known for their high load capacity, journal bearings can support heavy machinery and equipment.

- Ball Bearings: While ball bearings can handle significant loads, they are generally better suited for lighter applications compared to journal bearings.

Speed and Efficiency

- Journal Bearings: These bearings are efficient at lower speeds and require a continuous supply of lubricant to maintain performance.

- Ball Bearings: Ball bearings excel at high-speed applications, providing smooth and efficient operation with minimal friction.

Maintenance Requirements

- Journal Bearings: Require regular lubrication and monitoring to ensure optimal performance and longevity.

- Ball Bearings: Generally require less maintenance and are easier to replace if needed.

Making the Right Choice for Your Machinery

Choosing between journal and ball bearings depends on your specific machinery requirements. Here are some factors to consider:

Load and Speed Requirements

- For applications requiring high load capacity and lower speeds, journal bearings might be the better choice.

- For high-speed applications with moderate loads, ball bearings offer superior performance.

Maintenance and Longevity

- If you prefer a low-maintenance option with easy replacement, ball bearings are a good fit.

- For applications where durability and heavy-duty performance are essential, journal bearings are ideal.

Cost Considerations

- Journal bearings can be more cost-effective for heavy machinery due to their durability and load capacity.

- Ball bearings, while potentially more expensive, provide excellent performance for high-speed applications.

Environmental Considerations

- Journal Bearings: Often require continuous lubrication, which may involve environmental considerations regarding the disposal and management of lubricants.

- Ball Bearings: Generally have sealed designs that contain lubricants, reducing the need for frequent maintenance and mitigating environmental impacts.

Fusion Babbitting: Your Expert in Bearing Solutions

At Fusion Babbitting, we specialize in providing top-notch bearing solutions, including rebuilds, repairs, rebabbitting, reverse engineering, and custom manufacturing. Our team of experts can help you determine the best bearing type for your machinery, ensuring optimal performance and longevity.

Why Choose Fusion Babbitting?

- Expertise: With years of experience, we offer unparalleled knowledge in bearing solutions.

- Quality: We use high-quality materials and advanced techniques to deliver reliable and durable bearings.

- Customization: Our custom manufacturing services ensure you get the perfect fit for your specific needs.

Conclusion: Choosing the Best Bearing for Your Needs

Whether you need journal bearings for their high load capacity and durability or ball bearings for their high-speed efficiency, making an informed decision is crucial. At Fusion Babbitting, we are here to guide you through the process, ensuring you get the best bearing solution for your machinery. Contact us today to learn more about our services and how we can help you achieve optimal performance with the right bearings.