Understanding Babbitt Bearing Failure Analysis

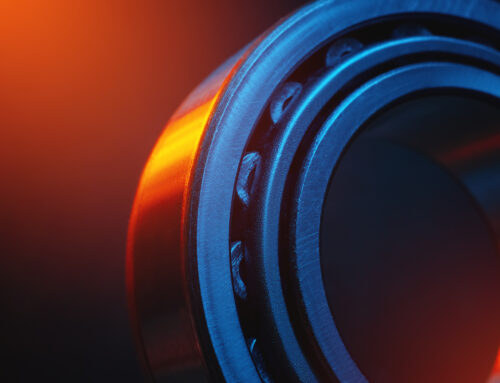

Babbitt bearings play a crucial role in the smooth functioning of industrial machinery. From electric motors to hydro power systems, their reliability and performance are paramount. However, like any mechanical component, Babbitt bearings can wear out over time. This is where a critical process, known as babbitt bearing failure analysis, comes into play. At Fusion Babbitting Co., Inc., we emphasize the importance of thorough analysis to determine the most cost-effective solution—repair or recast.

The Importance of Failure Analysis

Effective babbitt bearing failure analysis helps identify the root causes of bearing issues. This step is crucial in understanding whether a bearing can be saved through repair or needs to be recast entirely. The experts at Fusion Babbitting employ advanced diagnostic techniques to evaluate the extent of wear, cracks, or material fatigue.

Signs of Babbitt Bearing Deterioration

Several indicators suggest potential bearing failure:

– Increased operating temperatures due to friction.

– Unusual noises indicating metal-to-metal contact.

– Visible scoring, cracks, or deformations upon inspection.

– Reduced equipment efficiency or unexpected shutdowns.

Recognizing these signs early on allows for prompt action, either to repair or decide on recasting.

When to Consider Repair

Repairing Babbitt bearings can be a cost-effective solution if the damage is minor and detected early. Fusion Babbitting excels in providing high-quality repair services that meet or exceed OEM specifications. By opting for repair, you can often extend the life of the bearing without the need for complete replacement.

Techniques Used in Bearing Repair

Our skilled specialists employ several techniques:

– Rebabbitting: Recasting the affected areas with Babbitt metal to restore functionality.

– Centrifugal Casting: This ensures strong bond strength and bearing integrity.

– Arc Flame Spray Application: Used to restore worn components, carefully machined back to original specifications.

Advantages of Repair

Repair offers several benefits:

– Cost Savings: Repair is generally more affordable than replacement.

– Reduced Downtime: Repairing a bearing can often be quicker than fabricating a new one.

– Sustainability: Extending the life of existing components contributes to sustainability by reducing waste.

When Recasting is Necessary

Despite the benefits of repair, there are instances where recasting is inevitable. If the bearing material is severely compromised or the damage is beyond repair, manufacturing a new bearing may be the only feasible option.

Factors Leading to Recasting

Consider recasting if:

– The bearing has extensive damage that affects its structural integrity.

– There is repeated failure even after repairs.

– Modernizing or upgrading to new specifications is required.

Recasting Services at Fusion Babbitting

At Fusion Babbitting, we specialize in producing custom, high-precision bearing products for OEMs. Our recasting process involves:

– Using certified Babbitt materials to ensure high-quality outputs.

– Leveraging reverse engineering to create precise replicas of outdated bearings.

– Implementing cutting-edge fabrication and machining techniques for comprehensive solutions.

Our new manufacturing capabilities can handle components up to 120 inches in diameter and length, mirroring OEM quality standards.

Industries We Serve

Fusion Babbitting caters to a diverse range of industries, ensuring machinery operates smoothly across various sectors:

– Aluminum Mills and Mines & Steel Mills.

– Cement & Chemical Plants and Crushed Stone Producers.

– Electric Utilities, including Fossil & Nuclear Plants.

– Hydro/Pump Storage and Marine Repair.

– Motor Repair Shops and Paper Mills.

– Shipyards, providing essential marine components.

Applications of Babbitt Bearings

Our specialized services are ideal for crucial machinery such as:

– Electric Motors, ensuring optimal performance.

– Hydro Power Systems, maintaining energy efficiency.

– Pumps and Turbines, vital for industrial operations.

Why Choose Fusion Babbitting?

With over 40 years of combined expertise, Fusion Babbitting is dedicated to improving the quality and performance of industrial bearings. Our Milwaukee-based facility, at 4540 W. Burnham St., is equipped with advanced tools and a team of skilled specialists committed to delivering high-quality services.

Comprehensive Services

We offer:

– 24-hour emergency services for rapid response and minimized downtime.

– Nationwide service, ensuring accessibility and convenience for our clients.

– Precision-oriented solutions meeting OEM standards for reliability.

Contact Information

Address: 4540 W. Burnham St., Milwaukee, WI 53219

Phone: 414.645.5800 | Toll-Free: 800.613.5118

Email: sales@fusionbabbitting.com

The Decision is Clear

Ultimately, deciding between repair or recasting hinges on the results of a comprehensive babbitt bearing failure analysis. At Fusion Babbitting Co., Inc., we offer expert guidance to help you make informed decisions, ensuring your machinery runs smoothly with minimal disruptions.

By choosing Fusion Babbitting, you invest in quality, expertise, and a commitment to excellence. Start saving now by contacting us for a thorough evaluation and tailored solutions for your babbitt bearing needs.

Fusion Babbitting: Future-Proof Your Machinery

In an ever-evolving industrial landscape, ensuring the longevity and reliability of your machinery is paramount. Fusion Babbitting not only focuses on repairing or recasting but also on innovations that lead to improved performance. Our dedication to ongoing research in bearing technology ensures that we remain at the cutting edge, offering you solutions that are not just for today but are future-proof.

With our strategic approach, we prioritize understanding the unique requirements of each client, adapting our offerings to best suit individual needs. From creating custom solutions that fit niche applications to providing expert advice on preventative maintenance, Fusion Babbitting stands as a pillar of support for industries aiming to optimize operations.

Invest in top-tier Babbitt bearing solutions and join a long list of satisfied clients who have experienced the Fusion difference. Our expertise, commitment, and customer-centric approach make us the ideal choice for industries that demand precision, reliability, and innovation from their components.

Contact Fusion Babbitting today and discover how we can assist in safeguarding the future of your operations with our unmatched babbitt bearing solutions.