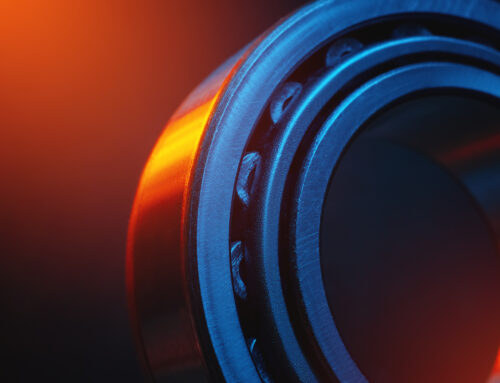

What is babbitt bearing axial load and why it matters

Babbitt bearings support rotating shafts in critical equipment like motors, pumps, turbines, and hydro systems. In most machines, journal bearings carry radial load while thrust bearings or thrust faces carry axial load. Axial load is the force that tries to move the shaft along its axis. When the babbitt bearing axial load rises above design limits, or when thrust forces are not balanced, the oil film can fail. That can lead to metal contact, wipe, cracking, and a fast decline in bearing health. If left unchecked, a small axial thrust problem can become a major rebuild or a full machine outage.

Fusion Babbitting has seen this pattern across many industries. Sudden changes in process conditions, misalignment, or tight clearances can push bearings past their safe window. Knowing the signs of risky babbitt bearing axial load helps you act early and avoid unplanned downtime. The goal is to catch thrust distress while you still have options to repair or rebabbitt on your schedule.

Common babbitt bearing axial load symptoms you should not ignore

Axial load problems often show up before a failure. If you see any of the warnings below, plan an inspection and gather data quickly.

- Rising thrust pad or thrust face temperatures compared to baseline

- Uneven temperature between thrust pads on the same bearing

- Axial vibration peaks that grow with speed or process changes

- Reduced shaft endplay or endplay that goes to zero during operation

- Abnormal wear marks on thrust collars, pads, or shoulders

- Discolored or wiped areas on the babbitt surface

- Metal debris or silver colored fines in filters or oil samples

- Frequent thrust position alarms on proximity probes

- Changes in coupling movement or mechanical seals that run hot

- Audible rubbing, especially during starts, load swings, or stops

If your machine has a history of thrust issues, even a small temperature split between pads can point to a repeat event. It pays to compare the current condition to your last healthy baseline. Where no baseline exists, create one after your next rebuild so you can spot drift early.

Why harmful axial thrust develops in babbitt bearings

The root causes of unsafe thrust forces vary by machine type and duty cycle. In general, one or more of the factors below drive the increase in babbitt bearing axial load.

Mechanical and installation factors

- Misalignment of couplings or shafts that pushes the rotor axially

- Piping strain or soft foot that distorts the housing

- Poor thrust collar finish or incorrect collar geometry

- Incorrect bearing clearances or pad tilt after previous repairs

- Thermal growth not accounted for during alignment at ambient conditions

- Improper assembly of spacers, shims, or preload elements

- Unbalanced rotor that migrates axially under dynamic forces

Process, lubrication, and environment factors

- Low oil flow or low oil pressure that thins the hydrodynamic film

- High oil temperature that reduces viscosity and film strength

- Contamination in oil that scores thrust faces

- Process upsets that change hydraulic thrust in pumps and turbines

- Transient load reversals in hydro and pump storage applications

- Start stop cycles that create repeated boundary contact

Electrical and control related factors

- Motor electrical issues that drive asymmetrical forces

- Shaft currents that damage bearing surfaces and disrupt the oil film

- Control valves or VFD tuning that cause surge, cavitation, or oscillation

Most real world failures include a stack of issues. For example, mild misalignment plus hot oil and a rough thrust collar can combine to push the babbitt past its limit. That is why a thorough inspection looks at fit, geometry, and operating conditions together.

How to diagnose babbitt bearing axial load problems

You can do many useful checks in the field before teardown. The steps below will help you confirm whether axial thrust is the main driver.

- Record baseline data. Capture current thrust and journal temperatures, axial vibration, oil pressure, oil temperature, and load. Compare to past records or OEM guidance.

- Measure shaft endplay during a stop. Use a dial indicator to check endplay cold. Look for endplay that is less than expected or that binds at one limit.

- Check thrust position if equipped. Many machines include probes that track rotor axial position. Look for drift toward one side as load increases.

- Review oil condition. Pull a sample for viscosity, particle count, water, and wear metals. A rise in tin or lead may indicate babbitt distress.

- Inspect the oil system. Verify pump operation, filters, coolers, and orifices. Low flow is a common root cause.

- Listen for rubbing. During run up and coast down, listen near the bearing. Intermittent noise can reflect boundary contact on the thrust faces.

- Review alignment and soft foot. Recheck the base, shims, and coupling fit. Correct any soft foot and remeasure.

- Examine thermal growth. Compare hot alignment targets to actual running temperatures. Correct targets if needed.

- Assess process variables. In pumps, look at suction conditions, cavitation risk, and discharge changes. In turbines and hydro units, review load swings and reversal events.

These checks help you decide whether to keep operating, plan a controlled stop, or schedule a rapid rebuild. If damage is found, document pad patterns, contact zones, and all clearances during teardown. Good notes help avoid repeat problems.

When a rebuild is likely unavoidable

Certain findings point to an imminent babbitt bearing rebuild. If you see any of the conditions below, consult a trusted shop right away.

- Babbitt wipe with visible smear or flow on the thrust face

- Cracks in the babbitt layer or bond failure at the backing

- Severe scoring on thrust pads or thrust collar

- Hot spots that created localized discoloration on pads

- Significant loss of endplay or a rotor that runs against a stop

- Large amounts of nonmagnetic metallic debris in the housing

Continuing to run with these findings can lead to secondary damage in the shaft, collar, or housing. An experienced rebabbitting partner can restore geometry, clearances, and oil film conditions to safe levels and can also advise on system changes that reduce future axial load risk.

How Fusion Babbitting rebuilds bearings affected by axial load

Since 1988, Fusion Babbitting Co., Inc. in Milwaukee has specialized in bearing repair, rebabbitting, rebuilding, reverse engineering, and new manufacturing. The team combines advanced equipment with hands on skill to deliver reliable results for demanding service. When axial load drives damage, their approach focuses on both the bearing and the system that feeds it.

A typical Fusion Babbitting rebuild workflow

- Incoming inspection. Detailed measurements, photos, and non destructive testing to confirm damage and bond condition.

- Reverse engineering if drawings are not available. Fusion Babbitting creates accurate drawings and models of obsolete or one off designs.

- Preparation and cleaning. Old babbitt removal, grit blasting, and surface prep to ensure a strong new bond.

- Centrifugal casting with certified Babbitt alloys. This method produces a high integrity bond and uniform lining thickness.

- Arc flame spray for worn housings or journals as needed. Sprayed layers are machined back to the original specification.

- Precision machining. Bores, shoulders, and thrust faces are brought to final size with tight control of runout and geometry.

- Oil groove and feature restoration. Grooves, dams, and pockets are cut to match OEM or improved designs.

- Contact and blue checks. Fusion Babbitting verifies proper contact patterns on thrust pads and collars.

- Final inspection and documentation. Clearances, finishes, and dimensions are recorded. The package includes recommendations to reduce babbitt bearing axial load at startup.

For large components, Fusion Babbitting can handle fabrication and machining for parts up to 120 inches in diameter and length. The company also manufactures new custom bearings for OEMs when upgrades or replacements make more sense than repair. With 24 hour emergency service and nationwide coverage, they help plants return to operation fast.

Preventing repeat axial load problems after a rebuild

A quality rebuild fixes the bearing, but the machine needs the right setup to stay healthy. Apply the practices below to keep babbitt bearing axial load in check.

- Set clear alignment targets that account for thermal growth. Validate with a hot recheck.

- Verify coupling fit, endplay, and axial stops. Confirm the rotor can move freely within limits.

- Balance the rotor and correct soft foot to avoid side loading or thrust bias.

- Improve oil system reliability. Check pumps, reliefs, filters, coolers, and heater control. Set alarms for low flow and high temperature.

- Select the proper oil viscosity for your temperature range. Review OEM guidance and field data.

- Polish or replace the thrust collar to the correct finish and geometry.

- Add or tune axial position monitoring where possible. Use trend data to catch drift.

- Control process upsets. In pumps, operate near best efficiency point to limit hydraulic thrust.

- Plan a gentle run in. Ramp load and temperature gradually and watch thrust pad temperatures.

Fusion Babbitting provides practical guidance on these steps. Their team reviews your data and helps you adjust oil, alignment, and component selection so the bearing runs within its safe window.

Industry specific notes on axial thrust

Hydro and pump storage

Load reversals and quick changes are common in hydro units. Bearings must tolerate thrust in both directions. Regular monitoring of pad temperatures on both sides is vital. Fusion Babbitting supports hydro and pump storage operators with fast turnarounds on thrust assemblies and collars.

Pumps in chemical, cement, and paper mills

Process shifts can move the pump away from its best efficiency region. That increases hydraulic thrust. Watch suction conditions and avoid cavitation. Fusion Babbitting rebuilds pump bearings and restores fits that maintain strong oil films under variable loads.

Motors, fans, and blowers

Misalignment, soft foot, and thermal growth often push rotors axially. Balance and proper foot correction reduce thrust bias. Fusion Babbitting partners with motor repair shops to deliver precision lined bearings that start true and stay stable.

Marine and shipyards

Propeller thrust and variable sea conditions drive large axial forces. Proper thrust collar finish and cooling are essential. Fusion Babbitting supports shipyards with emergency repairs and durable coatings.

Steel mills, mines, and aluminum mills

Heavy duty cycles and heat elevate oil temperature. Viscosity control and strong film formation matter. Fusion Babbitting’s centrifugal casting and careful machining help bearings survive long shifts and high loads.

Signs your equipment is ready for a professional evaluation

If you see one or more of these patterns, call for help before the next run.

- Repeated thrust pad temperature alarms even after minor adjustments

- Endplay readings that change over a few weeks

- Abnormal thrust collar wear after a recent rebuild

- Ongoing oil contamination despite filter changes

- Visible wipe or cracking during a minor inspection

An expert review can save the thrust faces and prevent a shaft repair. Fusion Babbitting offers inspections, reverse engineering, and fast rebuilds that meet or exceed OEM specifications.

Why plants choose Fusion Babbitting for axial load related repairs

- Established in 1988 with a nationwide reputation for quality

- Centrifugal casting with certified Babbitt materials for strong bonds

- Arc flame spray restoration for worn components

- Reverse engineering to replicate obsolete bearings with accurate drawings

- General fabrication and machining for large components up to 120 inches

- New manufacturing for OEM grade precision and performance

- 24 hour emergency service to minimize downtime

Fusion Babbitting blends experience and modern equipment to deliver long lasting results. Their technicians understand how axial load affects oil film behavior, pad geometry, and running clearances. That knowledge helps them tailor each rebuild to the real operating conditions of your machine.

How to start a successful rebuild project

- Gather data. Provide temperatures, vibration, oil reports, clearances, and photos.

- Ship the bearing assembly or arrange on site inspection.

- Review a repair plan. Ask for a clear scope, materials, and delivery timeline.

- Confirm improvements. Agree on any upgrades that reduce babbitt bearing axial load risk.

- Plan commissioning. Set monitoring and run in steps for a safe restart.

Fusion Babbitting keeps communication clear from quote to delivery. You will know what to expect, how the bearing will be rebuilt, and how to run it to avoid repeat thrust distress.

About Fusion Babbitting

Fusion Babbitting Co., Inc. is based at 4540 W. Burnham St., Milwaukee, WI 53219. Since 1988, the company has delivered bearing repair, rebabbitting, rebuilding, reverse engineering, and custom manufacturing to clients nationwide. Their focus is high quality work that meets or exceeds OEM specifications. The team supports industries that include aluminum mills, cement and chemical plants, fossil and nuclear plants, hydro and pump storage, marine repair, mines and steel mills, motor repair shops, paper mills, shipyards, and crushed stone producers. Applications include electric motors, hydro power systems, pumps, and turbines.

To discuss a babbitt bearing axial load issue or schedule a rebuild, contact Fusion Babbitting at 414.645.5800 or toll free at 800.613.5118. You can also email sales@fusionbabbitting.com for quotes and technical support.

Key takeaways for plant teams

- Babbitt bearing axial load problems rarely fix themselves. Monitor and act early.

- Watch thrust temperatures, endplay, oil condition, and axial vibration for trends.

- Address root causes during the rebuild. Improve alignment, oil system health, and collar condition.

- Partner with a specialized rebabbitting shop. Precision casting, machining, and inspection are vital.

- Use a measured restart and validated targets to protect the new bearing.

When it comes to axial thrust, the best defense is a strong oil film supported by correct geometry and stable operating conditions. Fusion Babbitting helps you achieve all three. From emergency repairs to planned upgrades, their team delivers the quality and speed you need to keep critical assets online.

Ready to reduce babbitt bearing axial load and extend bearing life

If your equipment shows signs of axial thrust distress, take the next step now. Fusion Babbitting will help you diagnose the cause, rebuild the bearing, and put controls in place to prevent repeat issues. Call 414.645.5800, toll free at 800.613.5118, or email sales@fusionbabbitting.com. Protect your schedule, your equipment, and your bottom line with a proven rebuild partner.