Overview: Why the Right Babbitt Alloy Matters

Choosing the right babbitt alloy is one of the most important decisions you can make for pumps, turbines, and motors in utilities and desalination plants. The wrong choice can shorten bearing life, raise operating costs, and increase the risk of unplanned downtime. The right choice improves performance, reduces energy use, and extends service intervals. This guide explains how tin-based and lead-based babbitt perform in wet, corrosive, and high-load environments so you can make a confident decision for your plant.

Fusion Babbitting Co., Inc. has helped facilities nationwide select and apply the best babbitt alloy for critical equipment since 1988. From repair and rebabbitting to reverse engineering and new manufacturing, our team supports power generation and water treatment operations with fast, precise solutions and 24-hour emergency service.

What Is Babbitt Alloy and How Does It Work

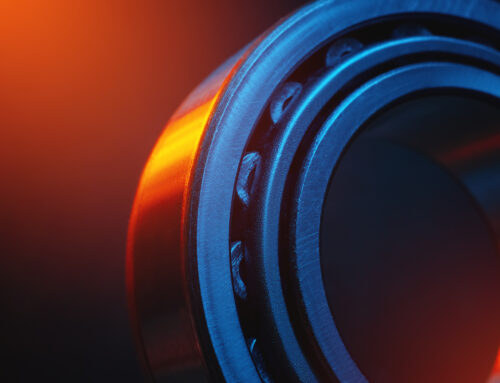

Babbitt alloy is a soft, conformable bearing metal cast or bonded to a rigid backing such as steel or bronze. It creates a low-friction surface that supports a hydrodynamic oil film between rotating and stationary parts. When the oil film is stable, metal-to-metal contact is minimal, heat is carried away, and the bearing runs smoothly.

Most babbitt alloys are either tin-based or lead-based with controlled amounts of antimony and copper. The hard intermetallic particles provide load capacity, while the softer matrix offers embeddability and conformability. The result is a bearing material designed to protect journals, absorb small contaminants, and run quietly across a range of conditions.

Tin-Based vs Lead-Based Babbitt Alloy for Utilities

Strengths of Tin-Based Babbitt

Tin-based babbitt is the common choice for high-speed, high-temperature, and corrosive environments. For many utility and desalination assets, these alloys provide dependable service where water or brine exposure is likely. Key benefits include:

- Higher fatigue strength for high-speed shafts and heavy dynamic loads

- Improved corrosion resistance in moisture-rich and chloride-laden atmospheres

- Better thermal conductivity to help dissipate heat

- Stable performance during frequent starts and stops

- Reliable service in clean oil systems with tight clearances

These qualities make tin-based babbitt a leading choice for boiler feed pumps, condensate pumps, steam turbines, and high-pressure pump bearings that must handle variable demand and potential process upsets.

Strengths of Lead-Based Babbitt

Lead-based babbitt is valued for its cost effectiveness and forgiving fit in large, slower speed equipment. When the operating temperature is moderate and the oil system is well maintained, lead-based babbitt can deliver long service life. Key benefits include:

- Strong embeddability to capture small particles and avoid scoring

- Good conformability for slight misalignment in large housings

- Attractive initial cost, often with faster lead times

- Stable performance in moderate-speed, heavy-duty applications

These traits are useful for large motors, gearboxes, and certain process pumps that run at steady conditions and do not face high surface speeds or extreme temperatures.

Limitations to Consider

Every alloy has limits. Tin-based babbitt costs more and can be less forgiving of poor lubrication practices. Lead-based babbitt handles contamination well but has lower fatigue strength and less corrosion resistance in wet or chloride-rich environments. Understanding your duty cycle, oil condition, and expected temperature range is critical when selecting a babbitt alloy.

Desalination Challenges and the Best Babbitt Alloy Response

Chloride Exposure and Corrosion

Desalination plants handle seawater, brine, and spray that can find their way into bearing housings during seal failure, washdowns, or maintenance events. Tin-based babbitt typically resists corrosion better than lead-based babbitt when exposed to chlorides. If your staff reports rust-tinted oil, brine contamination, or frequent seal changes, a tin-based babbitt alloy is generally the safer choice for critical pumps and turbines.

Temperature and Start-Stop Duty

Reverse osmosis high-pressure pumps and energy recovery turbines often see changing loads and frequent starts. Tin-based babbitt handles thermal cycling and transient loads well. Lead-based babbitt can be adequate for auxiliary and low-speed service where temperature rise is modest. For any unit with repeated start-stop duty, tin-based babbitt provides a wider safety margin.

Erosion, Cavitation, and Debris

Even with strong filtration, desal processes can introduce fine grit and scale. Lead-based babbitt excels at trapping small debris in its softer matrix, which can save journals from scoring. When filtration is excellent and seals are robust, tin-based babbitt still wins for speed and heat. Many plants use tin-based babbitt for their most critical rotating equipment, while using lead-based babbitt in slower speed auxiliary assets that accept occasional contamination.

Key Factors to Compare Before You Choose

Before you finalize a babbitt alloy, review the operating envelope. Fusion Babbitting guides clients through the following checkpoints to build a strong case for tin or lead:

- Speed and load: shaft surface speed and unit load at the bearing

- Temperature: oil inlet temperature and expected bearing metal temperature

- Lubrication: oil viscosity, filtration, and cleanliness targets

- Contaminants: water, brine, grit, or process chemicals that could enter housings

- Alignment: housing geometry, shaft runout, and thermal growth

- Duty cycle: continuous run, frequent starts, or intermittent service

- Maintenance: predictive monitoring, oil analysis, and spare strategy

Lifecycle Cost: Beyond the Alloy Price

It is tempting to compare babbitt alloy options only by purchase price. A lifecycle approach gives a clearer picture and often lowers total cost. Consider the following drivers:

- Initial cost: alloy, casting method, machining, and lead time

- Energy use: friction and temperature affect power draw

- Maintenance: oil changes, filter replacements, and inspections

- Downtime: planned outages and unplanned failures

- Service life: time to first rebabbitt and intervals between rebuilds

- Risk: consequences of failure for safety, product, and environmental compliance

In high-consequence assets found in utilities and desalination, tin-based babbitt often lowers lifecycle cost even with a higher initial price. In steady, moderate conditions with strong oil cleanliness, a lead-based babbitt bearing can achieve long service life at lower cost. Fusion Babbitting helps clients model both paths so you can choose with confidence.

Standards, Safety, and Environmental Notes

Many plants must align with internal standards, industry norms, and environmental rules. When you consider lead-based babbitt, your team should review handling procedures, workplace safety, and waste management requirements. With tin-based babbitt, corrosion performance and temperature capability are often the main checkpoints. Fusion Babbitting uses certified babbitt materials and established casting and machining methods to meet or exceed OEM specifications and your site standards.

Where Tin and Lead Babbitt Make Sense in Utilities and Desalination

Typical Matches by Asset

- Boiler feed pumps: tin-based babbitt for speed, heat, and reliability

- Condensate pumps: tin-based babbitt for corrosion protection and fast starts

- Steam turbines: tin-based babbitt for fatigue strength and temperature margins

- RO high-pressure pumps: tin-based babbitt for chloride exposure and thermal cycling

- Seawater intake pumps: tin-based babbitt for corrosion, lead-based for low-speed reserve units when allowed

- Brine recirculation pumps: tin-based babbitt preferred due to chlorides and temperature

- Large motors and gearboxes: lead-based babbitt can be suitable for slow to moderate speeds with clean oil

These are general guidelines. Your exact choice should follow a review of speed, load, lubrication, and environment. Fusion Babbitting provides that review as part of every repair or new manufacture project.

Common Failure Modes and How Alloy Choice Helps

- Wiping and smear: often tied to oil starvation or high temperature. Tin-based babbitt resists fatigue damage better at speed.

- Corrosion pitting: more common with brine ingress. Tin-based babbitt provides stronger resistance.

- Scoring from debris: lead-based babbitt can capture fines in its soft matrix, protecting journals.

- Thermal cracking: seen with repeated thermal shock. Tin-based babbitt offers better fatigue resistance.

- Edge loading: caused by misalignment. Both alloys benefit from precise machining and proper geometry.

How Fusion Babbitting Supports Your Bearing Program

Fusion Babbitting Co., Inc., established in 1988 and based in Milwaukee, Wisconsin, is a full-service bearing partner for utilities and desalination operators across the United States. Our team combines over 40 years of expertise with advanced equipment to deliver dependable, fast results.

Core Services for Utilities and Desalination

- Repair, rebabbitting, and rebuilding that meet or exceed OEM specifications

- Centrifugal casting for strong bond strength and consistent bearing integrity

- Arc flame spray application to restore worn components, then machine back to spec

- Reverse engineering to create precise replicas of obsolete bearings with drawings

- General fabrication and machining for components up to 120 inches in diameter and length

- New manufacturing for OEM-grade, high-precision bearing products

Fusion Babbitting serves aluminum mills, cement and chemical plants, fossil and nuclear plants, hydro and pump storage, marine repair, mines and steel mills, motor repair shops, paper mills, shipyards, and crushed stone producers. Our team understands the daily demands of electric motors, pumps, turbines, and hydro power systems, and we tailor our work to your load and speed profile.

Our Process for Selecting and Applying the Right Babbitt Alloy

- Application review: gather speed, load, oil type, temperatures, and failure history.

- Material selection: match tin-based or lead-based babbitt to the duty and risk profile.

- Shell preparation: inspect, clean, and prep the backing for optimal bond.

- Centrifugal casting: pour certified babbitt to achieve uniform density and strong adhesion.

- Precision machining: finish to clearances and geometry that meet or exceed OEM specs.

- Quality checks: non-destructive testing, dimensional inspection, and surface verification.

- Documentation: provide material certifications and final inspection data.

- Support: installation guidance, break-in recommendations, and oil system advice.

This structured approach helps your bearing achieve its intended service life from day one.

Maintenance and Operating Tips to Extend Bearing Life

- Oil cleanliness: set targets for particle counts and water content and inspect filters regularly.

- Seal integrity: monitor seals and replace promptly if leakage appears.

- Temperature tracking: trend bearing metal temperatures and investigate rises early.

- Alignment: verify shaft and housing alignment at installation and after thermal cycles.

- Break-in procedure: follow controlled ramp-up and oil flow checks after rebuilds.

- Oil selection: use the correct viscosity for your speed and temperature range.

- Predictive tools: combine vibration analysis with oil analysis for early detection.

Fusion Babbitting can advise your team on practical steps that match your alloy choice and duty cycle.

Quick Decision Guide: Tin-Based or Lead-Based Babbitt Alloy

- Choose tin-based babbitt if you face high speeds, higher temperatures, chlorides or water ingress, frequent starts, or critical uptime demands.

- Choose lead-based babbitt if your equipment runs at moderate speeds, with clean oil, stable temperatures, and you value embeddability and lower initial cost.

When in doubt, consult with a specialist. Fusion Babbitting will review your data and recommend the best babbitt alloy and geometry for your goals.

Why Partner With Fusion Babbitting

Reliable bearings support reliable plants. Fusion Babbitting pairs deep babbitt alloy knowledge with precise manufacturing to reduce risk and total cost for utilities and desalination operations. Our centrifugal casting process, certified materials, and exact machining help bearings carry the loads and speeds you specify. Our reverse engineering and arc flame spray services keep aging assets in service with updated materials and improved fit.

We back every job with responsive communication and 24-hour emergency support. Whether you need one thrust pad rebuilt or a full set of pump bearings manufactured, our team moves quickly to protect your schedule and budget.

FAQ: Babbitt Alloy for Utilities and Desalination

Is tin-based babbitt always better than lead-based babbitt

No. Tin-based babbitt performs better in high-speed, high-temperature, and corrosive settings, but lead-based babbitt can be a smart choice for moderate-speed equipment with clean oil and tight maintenance practices. The best option depends on your duty cycle, environment, and risk tolerance.

What signs suggest I should switch alloys

Consider a switch if you see recurring corrosion pitting, smear at higher speeds, repeated start-stop distress, or oil contamination that overwhelms your current material. If you run critical assets where failure is costly, a tin-based babbitt upgrade may pay back quickly.

How does Fusion Babbitting ensure bond strength

We use centrifugal casting with certified babbitt materials and strict surface prep on the shell or backing. This process creates a strong, consistent bond that stands up to load and temperature swings.

Can you reproduce obsolete bearings

Yes. Fusion Babbitting provides reverse engineering with detailed drawings, material selection, and modern casting methods to replicate or improve obsolete or hard-to-source bearings.

How fast can you respond in an outage

We offer 24-hour emergency services and will prioritize critical utility and desalination components to minimize downtime. Contact our team to discuss your situation and timing.

About Fusion Babbitting

Fusion Babbitting Co., Inc. has delivered trusted bearing services since 1988 from our Milwaukee, Wisconsin facility at 4540 W. Burnham St. We support clients across the country with repair, rebabbitting, rebuilding, reverse engineering, and new manufacturing. Our equipment handles components up to 120 inches in diameter and length, allowing us to serve heavy industry and large rotating assets. We are committed to quality, speed, and clear communication on every project.

Contact Fusion Babbitting

Ready to choose the right babbitt alloy for your utilities or desalination equipment Contact Fusion Babbitting for a review of your application and a fast, practical recommendation.

Address: 4540 W. Burnham St., Milwaukee, WI 53219

Phone: 414.645.5800

Toll-Free: 800.613.5118

Email: sales@fusionbabbitting.com

Fusion Babbitting is your partner for dependable babbitt alloy selection, repair, and manufacturing. Reach out today to protect your schedule, extend bearing life, and control lifecycle cost for your pumps, turbines, motors, and hydro systems.