Understanding the Importance of Bearing Repair

Industrial bearings are crucial parts in heavy-duty machinery. These components bear loads, reduce friction, and help machines operate smoothly. When large bearings begin to fail, repairing them quickly becomes necessary to prevent breakdowns and production loss. Whether in electric motors, turbines, or industrial pumps, fixing massive bearings is essential to maintaining safety and top performance.

Fusion Babbitting Co., Inc. has been a trusted leader in the field of industrial bearing repair since 1988. Based in Milwaukee, WI, Fusion Babbitting specializes in the repair, refurbishment, and manufacture of Babbitt bearings for a variety of industries across the United States. The company’s 24/7 emergency response and coast-to-coast support make it a reliable vendor when you need to repair bearing systems without delay.

Signs You May Need Bearing Repair

Knowing when it’s time to fix a bearing problem can save your equipment from bigger issues. Be aware of these warning signs that indicate it’s time to repair bearings:

– Unusual or loud noises from rotating equipment

– Excessive vibration during machine operation

– Overheating near bearing housings

– Scoring, pitting, or visible wear on bearing surfaces

– Machinery that underperforms or shows declining efficiency

These signs are early indicators that something is wrong. When caught early enough, you can often repair bearing issues before they result in costly equipment failure or extended downtime.

What to Know Before Calling a Vendor

Understand Your Bearing Type

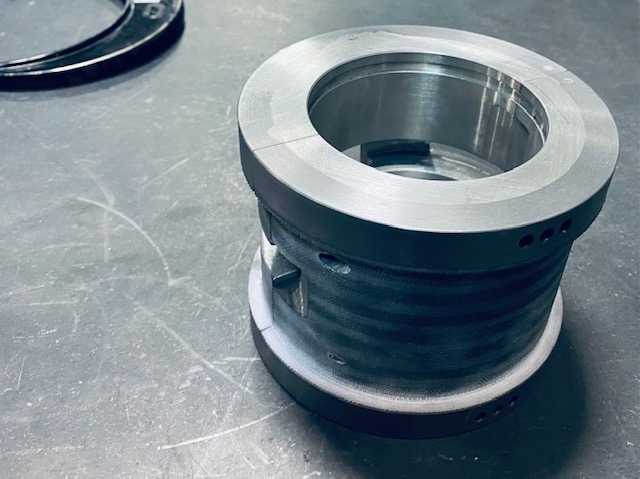

Before you reach out to a service provider, it helps to know whether your equipment uses Babbitt bearings. These types of bearings are made by applying a special soft metal alloy onto a shell, which withstands high loads and provides great durability and lubrication. They’re used in major systems like turbines, pumps, motors, and large generators. Giving this information upfront to Fusion Babbitting lets them make a quicker and better assessment of what will be needed to repair your bearing system.

Know Your Equipment Specs

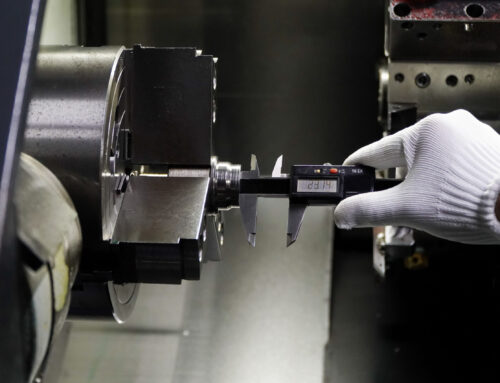

Prepare any available data on your machine. Important details include part numbers, manufacturer name, bearing dimensions, and the machinery’s serial number. If you have OEM drawings or technical blueprints, even better. Fusion Babbitting uses these specs to ensure that when they fix or rebuild bearings, they deliver results that meet or exceed original manufacturer expectations.

Evaluate the Extent of the Damage

Many bearing problems come from lubrication issues, misalignment, or long-term wear and tear. Depending on how extensive the damage is, the repair solution might vary—from straightforward rebabbitting of a bearing surface to a complete rebuild or fabrication of a new component. Visual damage or performance symptoms should always be noted. When you contact Fusion Babbitting, their team will review your bearing’s condition and recommend the best course of action for a lasting repair.

Why Choose a Specialized Bearing Repair Partner?

Expertise in Large Bearing Services

Repairing giant industrial bearings is something that only seasoned professionals should handle. It requires precise tooling, deep knowledge of metallurgy, and experience working with heavy equipment. Fusion Babbitting brings more than 40 years of combined team experience, particularly in dealing with large Babbitt bearings across sectors like energy, marine, steel production, and mining.

Capabilities for Complex Jobs

Fusion Babbitting is equipped to handle all levels of bearing repair and rebuilding. Here are some of their specialized services:

– Comprehensive bearing repair, rebuilding, and rebabbitting

– Centrifugal Casting for consistent and durable Babbitt metal layers

– Arc Flame Spraying to restore surface profiles prior to final machining

– Reverse Engineering to replace obsolete or hard-to-find components

– Custom Machining for parts up to 120 inches in diameter

These capabilities make Fusion Babbitting a full-service solution provider when it’s time to repair bearing systems that other shops can’t handle.

Industries That Benefit From Professional Bearing Repair

Fusion Babbitting supports a wide variety of industries that simply can’t afford downtime due to failed bearings. Their precision work helps maintain operations across many critical fields, including:

– Hydro and pump storage systems

– Fossil fuel and nuclear energy plants

– Cement and chemical manufacturing

– Aluminum and steel mills

– Marine shipping and offshore operations

– Mining, aggregates, and crushed stone processing

– Paper mills and large-scale electric motor shops

If any of these sectors experience failed equipment, repair bearing services are required fast. Fusion Babbitting’s ability to respond quickly and repair on a national level makes them a go-to provider trusted by many of the nation’s largest manufacturers.

Common Applications That Need Large Bearing Repair

Many of today’s most important machines rely on large Babbitt bearings for steady, continuous operation. These include:

– Industrial electric motors in processing plants

– Power plant turbines for hydroelectric and fossil fuel energy

– High-capacity pumps moving water, slurries, or chemicals

– Electrical power generators

When bearings in these systems fail, production halts, and repairs must be made quickly. Fusion Babbitting not only provides fast service but also manufactures or rebuilds components that perfectly match original parts, minimizing time lost to breakdowns.

The Role of Babbitt Bearings in Industrial Equipment

Babbitt bearings are designed for high load and rotating speed applications. The material’s soft nature prevents damage to steel shafts, while still allowing for long-term use. The Babbitt layer is applied, often using centrifugal casting for uniformity, then machined to extremely fine tolerances. This process ensures that once installed, the bearing delivers smooth rotation, minimal friction, and extended life.

Fusion Babbitting uses only certified Babbitt materials, paying strict attention to each casting and machining step. Because the quality of a bearing repair directly impacts reliability, choosing an expert like Fusion Babbitting is a wise investment. Their methods prevent premature failure and keep your systems running longer.

What Sets Fusion Babbitting Apart?

Fast, Reliable Service—Even in Emergencies

Equipment downtime can cost thousands by the hour. Fusion Babbitting offers fast response, even in emergency situations. Their 24-hour turnaround capabilities and ability to ship nationwide mean your equipment won’t sit idle for long. Located centrally in Milwaukee, WI, they can also coordinate logistics to and from your facility if needed.

High Standards and Quality Assurance

Fusion Babbitting’s repair processes are held to the strictest standards. Every job is carefully inspected, and only certified materials are used in the rebuilding of large bearings. Their skilled team makes sure the finished product performs like brand new—or better—by adhering closely to OEM guidelines or through custom reverse engineering if documentation is unavailable.

One-Stop Bearing Solutions

Whether you need new parts manufactured or existing ones rebuilt, Fusion Babbitting does it all. They’re capable of large-scale fabrication and custom machining for a range of industries. Their all-in-one approach saves time by reducing the need to involve multiple vendors or coordinate between casting and machining shops. Everything happens in one place, with experts who understand large bearing systems inside and out.

Steps to Take Before You Call Fusion Babbitting

To speed up the repair process and avoid delays, take these steps before calling for service:

– Describe the problem: Include any noise, heat, vibration, or loss of performance.

– Note equipment details: Model number, serial code, bearing size, and machine type.

– Collect drawings or specifications: Original manufacturer documents will help guide an accurate rebuild.

– Contact Fusion Babbitting: Call 414.645.5800 or 800.613.5118, or email sales@fusionbabbitting.com.

– Provide clear information: The more details you share, the quicker Fusion Babbitting can plan repairs that restore your operation.

Beyond Repairs: Fusion Babbitting’s Commitment to Longevity

In many cases, Fusion Babbitting doesn’t just restore damaged components—they improve them. By analyzing worn parts and updating them with better materials, refined designs, or improved castings, clients often find that rebuilt bearings from Fusion perform better than the originals. This proactive approach saves money and increases operational uptime.

Repeat customers continue to rely on Fusion Babbitting for more than just a one-time fix. Their long-term relationship approach focuses on quality, efficiency, and safety with every repair bearing job they complete. This commitment is why clients across North America trust Fusion Babbitting to keep their critical machines in top form.

Conclusion: Repair Bearing Problems with Confidence

If you’re dealing with giant, worn, or underperforming bearings in your equipment, take action early. Getting a reliable vendor to repair bearing components before failure not only protects your machinery but also saves you massive operational costs.

Fusion Babbitting stands out as the go-to expert in large bearing services. From fast response to reverse engineering and complete overhauls, the company has what it takes to support the most demanding industries. Their certified materials, quality focus, and advanced capabilities make a difference that customers notice right away.

Reach out to Fusion Babbitting at 4540 W. Burnham St., Milwaukee, WI 53219. You can call 414.645.5800 or toll-free at 800.613.5118, or email sales@fusionbabbitting.com for help with any large bearing needs.